Five new medical-grade polymers for biopharmaceutical manufacturing have recently been added to Solvay’s offerings.

Five new medical-grade polymers for biopharmaceutical manufacturing have recently been added to Solvay’s offerings.

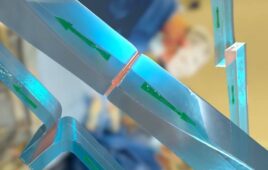

Solvay hopes to support the industry’s shift toward single-use peripherals, filtration, bioreactors and containment by adding a new portfolio of polymers to its product family.

The company created its new biopharmaceutical manufacturing portfolio using five product families in its offerings including Radel polyphenylsulfone (PPSU), Udel polysulfone (PSU), AvaSpire polyaryletherketone (PAEK), KetaSpire polyetheretherketone (PEEK) and Ixef polyarylamide (PARA).

Solvay determined the effect of gamma irradiation up to 50 Key on each polymer family before determining what materials would be best for its portfolio. The company wanted to make sure each polymer family would be able to keep its mechanical performance and other application-critical properties. Solvay found that the polymers were compatible with gamma irradiation, which is the preferred sterilization method for single-use systems.

All polymers are also certified under U.S. Pharmacopeia (USP) Class VI test standards before and after sterilization.