Vention Medical offers this 12 page brochure to discuss company capabilities. It is written by the company CTO Mark Saab. The Introduction and first page are here. For the rest: http://goo.gl/c6Zqpm

The demand for less-invasive medical procedures is a major driving force in the medical device industry today. Smaller and thinner is better, especially in catheters, endoscopes, and other devices inserted into the body. Designers are looking for new ways to downsize existing devices and satisfy the requirements of minimally invasive procedures. The industry is also under pressure to build more features into devices without increasing their profile (size). Thinwall heat shrink tubing can help designers meet this demand across a range of applications by reducing diameters and improving production processes. Vention Medical has developed a proprietary process to manufacture thin-wall heat shrink tubing from Polyester (specifically, polyethylene terephthalate, or PET) that exhibits extraordinary tensile strength, even with walls as thin as 0.00015 in.

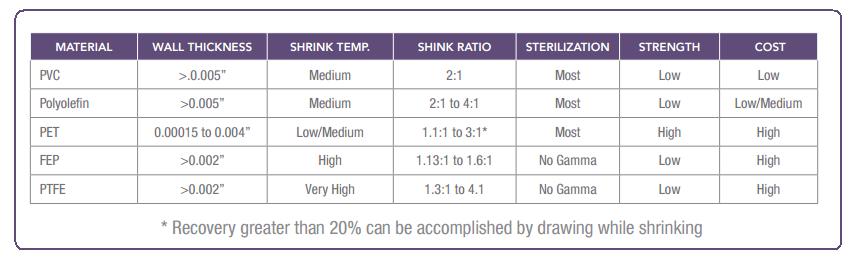

This paper begins with a brief comparison of the key properties of thermoplastic materials used in the manufacture of high-end medical heat shrink tubing, and then discusses the advantages of PET for thin-wall heat shrink tubing for the following applications:

► Creating variable-stiffness cCatheters

► Electrical insulation

► Protective covering and encapsulation & bundling

► Tube joining & transitioning

► Tube marking and printing

► Cather shaft lamination

► Catheter tip forming

► Micro hose clamps

► Masking procedures

PET is the clear leader in terms of thin walls and high strength. It is 10 to 100 times thinner than all other heat shrink tubing and more than 10 times stronger. Tube walls of 0.00015 to 0.004 in. can be produced from PET and still maintain high hoop strength. That compares with >0.002 in. for Fluoropolymers (FEP, PTFE) and >0.005 in. for Polyolefin and PVC. PET also has the lowest shrink temperature (185°F/85°C) of the group, which enables processing of delicate substrates without heat degradation.

As noted in the chart above, the cost of PVC is low, Polyolefin is low to medium, and Fluoropolymers and PET are higher. However, the cost of tubing for high-end medical devices is generally outweighed by other factors, such as the need for unique mechanical characteristics, product quality, precise sizing, availability across a broad range of diameters and wall thicknesses, and supplier delivery and reliability. In addition, cost savings can often be realized by using high-end components that eliminate upstream or downstream processes, reduce the defect rate, or deliver functional performance that warrants a premium price in the marketplace.

For the full brochure: http://goo.gl/c6Zqpm