Silicon Valley-based 3D printing company Carbon said today that it raised $81 million in a new funding round it plans to use for its medical device and auto part printing business.

Silicon Valley-based 3D printing company Carbon said today that it raised $81 million in a new funding round it plans to use for its medical device and auto part printing business.

The round was led by BMW Group and joined by new investors GE Ventures, Nikon, JSR and existing backers, bringing the total raised by the company up to $222 million. The company said it will release more details of additional strategic investors in the round in 2017, as well as details of future manufacturing projects.

“3D printing is a translation of the digital to a physical reality and when done right, offers true design freedom across every category. At launch we set forth a bold vision to fundamentally change how the world makes ‘things.’ We have been working to deliver on that vision for the U.S. market, and are ready to step onto the global stage,” Carbon co-founder and CEO Joseph DeSimone said in a press release.

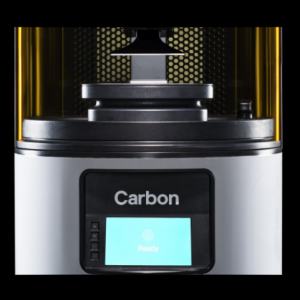

The company’s flagship is the M1 3D printing tool designed for product design, functional prototyping and at-volume manufacturing. The device uses a “range of materials” from 5 resin families; the company touts the materials as versatile enough to meet engineering requirements expected from injection molded polyurethane elastomer to glass-filled nylon and “many more.”

“In today’s digital world, additive manufacturing is changing how products are designed, made and serviced at GE. Carbon’s CLIP technology can print exceptional quality parts for end-use production, opening the doors to incredible possibilities like low volume manufacturing, freedom of design, and mass customization. We are excited to work with Carbon as part of our vision in deploying additive manufacturing applications across GE,” GE Ventures advanced manufacturing senior director Steve Taub said in a prepared statement.

Carbon said Nikon will use its technology in projects including 3D measurement and X-ray CT.

“We’re excited to partner with the innovative Carbon team to explore opportunities for Japanese and Asian expansion. In addition to bringing fundamental scientific advances to 3D printing, the company has executed relentlessly, putting its M1 machine into the hands of customers, and continuing to innovate on their machine, software, and resins,” Nikon senior veep Masao Nakajima said in a prepared release.

“The current 3D printing market, with the exception of very few, is a prototyping market. Carbon approached the challenge, and potential, of 3D printing from a very different perspective. With its M1 and CLIP technologies, Carbon has introduced a solution that will truly revolutionize manufacturing,” JSR corp prez Nobu Koshiba said in prepared remarks.