Four steps help design a better-than-standard fluid coupling.

Tyler Grubb, Design engineer, Medical Business Unit, CPC

Connectors – seemingly small components – have a significant impact on medical device design, function and user satisfaction. The wide capabilities of today’s couplings make devices easier and safer to operate. For instance, they can stop flow when lines are disconnected, detect the correct placement of multiple lines and even confirm the type of media being delivered. They can also relay valuable information such as temperature and pressure. Smart couplings can track batch numbers, expiration dates, and the number of uses for limited-use devices.

Custom connectors enhance the performance of a growing array of medical applications, including surgical and patient monitoring devices and in-vitro diagnostic tools. Custom parts meet exact performance requirements, extend a device’s functional capabilities, and differentiate products from the competition. Is a custom solution right for you? Here are four key steps to follow when working with a connector specialist to provide an ideal fluid coupling for your device:

1. Define your requirements – technical, price, and timing

Do your performance requirements extend beyond the capabilities of standard catalog parts? Do you want to reduce cost by integrating multiple components? Are your engineering resources focused on other sub-assemblies? If so, tap into the extensive capabilities and experience of a connector expert.

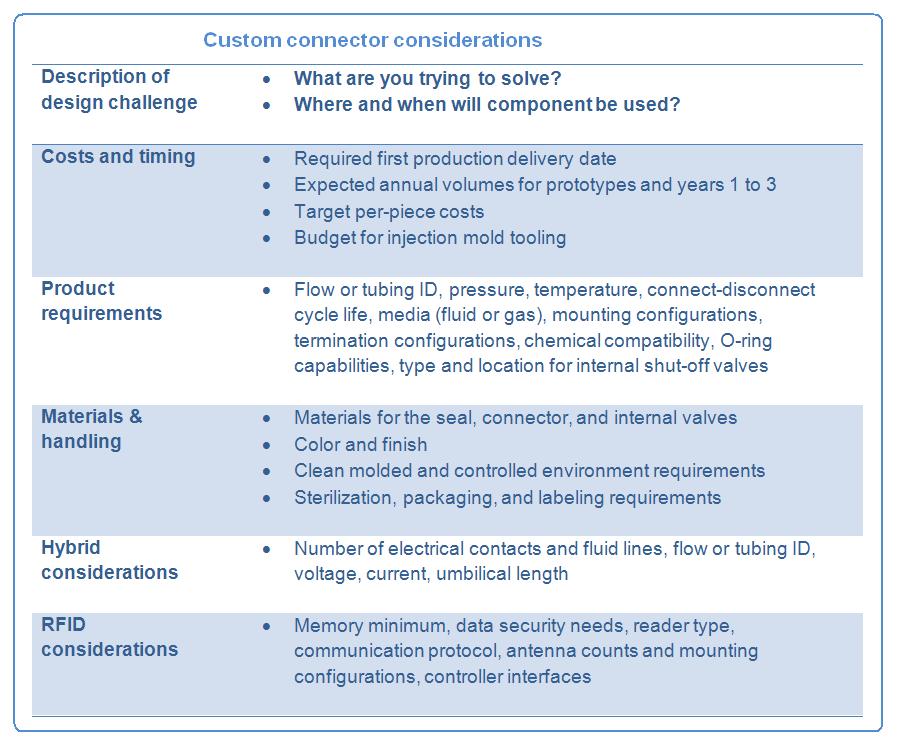

Hybrid connectors can consolidate multiple connections between remote tools and a device, and improve patient safety by eliminating misconnections. Such connectors allow fast, easy, simultaneous connection of multiple lines for electricity, fluids, or air.

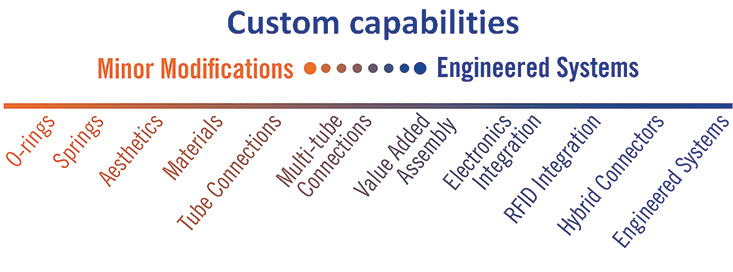

Simple custom modifications include incorporating a particular O-ring, spring or tubing material to address chemical or sterilization compatibility. Other straightforward projects include accommodating multiple fluid lines or adapting to unique tubing sizes or bottle caps. More advanced connectors might feature data lines, sensors, or radio-frequency identification (RFID). Whatever the complexity, highly qualified coupling suppliers invest significant time early in the process to understand design inputs for optimal custom outputs.

For example, the manufacturer of an emergency patient-monitoring system found that rough handling in the field broke the tubing connectors on their blood pressure cuff, creating leaks that required expensive service calls. The unique design of a custom coupling now protects the sealing surfaces and a locking mechanism maintains the female body’s alignment on the equipment, reducing strain and damage. The customer’s requirement to speed set-up and reduce user errors also led the coupling designer to integrate a mechanical sensor that detects the connection and automatically starts air flowing to the blood pressure cuff. One leak-free, customized solution minimized service costs, increased device quality and enabled new automated functions.

In addition to understanding specific design challenges, experienced connector suppliers should ask about required flow rates, inner tubing diameters, pressure and temperature parameters, intended media, potential shutoff valves, tubing interfaces, preferred materials, compatibility factors, applicable sterilization processes and specific packaging or labeling. More complex projects might also include electrical specifications (type and number of contacts, voltage, and current) or simultaneously managing lines for power, air, or fluid. Clarifying these design inputs up front generates the most relevant solution.

In addition to understanding specific design challenges, experienced connector suppliers should ask about required flow rates, inner tubing diameters, pressure and temperature parameters, intended media, potential shutoff valves, tubing interfaces, preferred materials, compatibility factors, applicable sterilization processes and specific packaging or labeling. More complex projects might also include electrical specifications (type and number of contacts, voltage, and current) or simultaneously managing lines for power, air, or fluid. Clarifying these design inputs up front generates the most relevant solution.

Broader project details are also important. For example, sharing a first-production delivery date, anticipated annual volumes and the targeted per-piece cost helps define suitable manufacturing methods, such as relying on machined components or investing in new injection-mold tooling. Experienced suppliers also identify the best approach to increasing volumes as you move through verification-and-validation builds to full production. Recommendations in this phase might include machining certain components or building soft aluminum tooling, to quickly evaluate injection molded parts before investing in multi-cavity tooling.

Detailed information, such as technical specs, timelines and budgets, lets a good supplier provide two or three preliminary concepts and associated unit pricing, ideally within two to three weeks – key information at go/no-go decision time.

2. Collaborate with the right design partner to offload your engineering burden

Your engineers might be swamped with other projects or unsure about how to develop the right connector quickly and efficiently. Although industrial design or prototyping firms have their place, they’re likely not connector specialists. The most qualified suppliers for a custom job focus largely, if not exclusively, on connectors.

Simplest modifications to a connector might be adjusting o-ring materials. Complexity in the design increases with each step to the right of the chart.

Ask potential partners for the number of custom connectors they produce on an annual basis and their experience working in your category. Close collaboration between client and vendor engineers streamlines development and increases the likelihood of success. Some suppliers offer no-cost engineering expertise and assistance as an investment in a long-term business relationship.

Comprehensive connector specialists also bundle standard and customized components, often sourcing materials for connector modifications from existing inventory. This saves money and mitigates risk by using already-tested solutions proven to perform in existing applications.

3. Prototype and test first

Fast feedback is critical when evaluating new design concepts for a custom connector. CAD models, 3D-printed components and other prototyping tools let multiple departments quickly assess fit, form and function. Soft injection-mold tooling – with its short lead times and ability to produce limited quantities – is another great option for comparing injection-molded parts before diving into new tooling and mass production.

A risk-based approach across the entire connector life cycle also contributes to a successful product. Supplier partners versed in ISO13485 can manage the design controls process and provide documentation indicating that the finished product meets initial requirements. Process controls – such as installation, operation and performance qualification (IQ, OQ and PQ) validations – seamlessly enter the design history file (DHF) to keep the project moving along.

Performance testing and in-depth material characterization confirm that a custom connector meets its intended use. For example, a standard connector made in polypropylene will fall apart when autoclaved at 250°F for 30 minutes. However, a customized stainless steel version withstands high temperatures and a longer list of disinfectants or reagent media. To mitigate leak risks, ask supplier partners for historical data and testing recommendations used in circumstances similar to your custom job.

4. Make it “smart” – add electronics, RFID and sensors

Data-transmitting fluid connectors include the coupling body (right), which houses an RFID reader, and the coupling insert (left), which incorporates an RFID tag capable of reading and conveying information.

Do you need to track batch numbers, expiration dates and the number of uses for single- or limited-use products? Maybe it’s critically important for device users to verify secure connections, correct line attachment or appropriate media. Smart connectors offer these performance characteristics.

For instance, the developer for an ocular surgery system incorporated RFID-enabled connectors into the disposable lines used between the main console and a surgical handpiece. These smart couplings convey information about individual patients, their intended surgeries and, accordingly, the appropriate device settings, contributing to patient safety and procedure speed and accuracy.

Custom work demands creativity, experience, confidence, responsiveness and a readiness to address unknowns. The best suppliers listen closely to design challenges and offer in-house engineering services, extensive modeling, prototyping and production capabilities and access to thousands of existing components expertly applied to your tailor-made solution.