Goodfellow and the German technology company Acquandas GmbH have formed a new partnership to offer device manufacturers micro-patterned, 2D and 2.5D integrated multi-function miniaturized components and coatings with superior performance properties.

Miniaturised Nitinol (NiTi) metallic components have been successfully produced by Acquandas down to as thin as 5 µm up to 80 µm with feature resolution of 1-10 µm.

This “state-of-the-art” thin film technology, which can be as thin as 5 µm (~0.0002 in.) up to 80 µm (~0.0031 in.), is produced by Acquandas in a range of materials including Nitinol (NiTi) and other superelastic or shape memory alloys, bioresorbable alloys, magnetic materials, electrical alloys and insulators. Leading manufacturing companies in healthcare and other industries looking to overcome problems and limitations with existing miniaturised components will be able to benefit from this new thin film materials technology, now available via Goodfellow, to develop next generation smart devices and instrumentation.

Acquandas is located on the University of Kiel campus where it has its offices, production units and use of the Institute for Materials Science ‘Kieler Nanolabor’ clean room and research laboratory facilities. All miniaturised components are custom designed and manufactured to order from CAD drawings using the proven thin film microsystem processes and techniques developed by the founders of Acquandas: Dr.-Ing Rodrigo Lima de Miranda, Prof. Dr.-Ing. Eckhard Quandt and Andreas Schüssler, PhD, who together set up the company in 2012 to commercialize their knowledge and expertise after many years of scientific work at leading research centres in Germany focusing on intelligent thin film materials, especially NiTi Shape Memory and Supereleastic materials.

Miniaturised Nitinol (NiTi) metallic components have been successfully produced by Acquandas down to as thin as 5 µm up to 80 µm with feature resolution of 1-10 µm.

According to Acquandas, and supported by several peer reviewed published articles in key material science journals (for example, Shap. Mem. Superelasticity, (2015) 1:286–293), it can batch manufacture the thinnest film based NiTi ‘smart alloy’ metallic components currently available. NiTi metallic components have been successfully produced by the Acquandas team at sub 80 µm miniaturization levels down to as thin as 5 µm with feature resolution of 1-10 µm (compared with 15 µm ± 5 µm for a conventional NiTi film) and with a very high level of purity. The high purity of the Acquandas NiTi film results in significantly enhanced “ultralow” fatigue endurance capabilities of its shape memory alloy thin films, proven under controlled test conditions, to be able to perform at least 10 million transformation cycles without any changes in functional behavior (NiTiCu alloy) (Science 348 (2015), 1004).

Independent comparative tests of conventional NiTi and Acquandas sputtered thin films have been carried out and published by Siekmeyer, et al., in the Journal of Material Engineering and Performance. Their findings include comparative graphs and data tables which clearly show the superior mechanical properties and fatigue behaviour of the Acquandas NiTi thin film, most notably up to 200% higher fatigue alternating strain data, reaching 1.4-1.5% (@ mean strain 1.5-2.0%) compared with only ~0.5% alternating strain levels for the conventional NiTi tested.

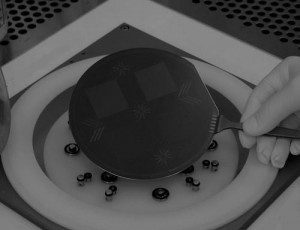

The fabrication of 2D structures is Acquandas base technology. Any 2D design can be chosen within the limits of the technology.

The proprietary Acquandas microsystem technology and techniques incorporate three key process interfaces: UV-lithography, magnetron sputtering and wet chemical etching, with final stages of the production process being heat treatment and shape setting. Two thin film fabrication modes are available to cover both initial new product development (for prototype and small volume development) and full scale manufacturing (for high volume production). Goodfellow will also provide customers with FEM and CAD based design training with this thin film technology and welcomes design development partner collaboration.

Acquandas thin film technology based components now offer device manufacturers major step change benefits in design scope, performance and product capabilities. Complex, next generation miniaturised smart devices can now be cost effectively developed and batch manufactured with significantly higher mechanical properties, increased integrated device functionality and a longer service life.

2.5 dimensional structures offer a limited degree of freedom into the third dimension.

New application opportunities are currently under development in healthcare to manufacture the next generation of self–expanding, biocompatible and bioresorbable implant devices and intelligent medical instruments. This miniaturised technology is also being increasingly applied in defence, aerospace, automotive, telecommunications, test equipment and manufacturing automation applications. Examples of industrial applications include the use of shape memory alloy based electrical actuators for robotic applications and latest microelectromechanical (MEMS) technology to manufacture miniaturized electronic relays, position sensing linear actuators, micro relays, micro valves and micro pumps.

This new partnership with Acquandas is part of an ongoing strategic focus by Goodfellow to expand its portfolio of materials and services for its global research and industry customer base, to be able to supply the very latest materials commercially available.

Acquandas

acquandas.com

Goodfellow

goodfellowusa.com

![A photo of the Medtronic GI Genius ColonPro polyp detection system flagging a potential sign of colon cancer during a colonoscopy. [Photo courtesy of Medtronic]](https://www.medicaldesignandoutsourcing.com/wp-content/uploads/2024/04/Medtronic-GI-Genius-doctors-268x170.jpg)