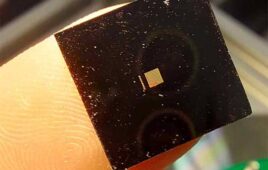

Awarepoint medical RFID asset tracking tags utilize bobbin-type LiSOCl2 batteries that do not have to be removed prior to high temperature autoclave sterilization, ensuring continuous and reliable data.

Lithium batteries are allowing medical devices to become smaller and more ergonomic without sacrificing power or performance.

Sol Jacobs, Tadiran Batteries

Modern medical devices are become increasingly sophisticated and miniaturized, demanding more for advanced battery-powered solutions.

Lithium batteries are paving the way by powering a wide variety of medical devices, including automatic external defibrillators, surgical power tools, robotic cameras, RFID asset tags, infusion pumps, bone growth stimulators, glucose monitors, blood oxygen meters and cauterizers. Lithium battery chemistry is preferred for delivering the highest specific energy (energy per unit weight) and energy density (energy per unit volume) of any battery type, along with nominal open circuit voltages ranging from 1.7V to 3.9V, which enables products to be miniaturized.

Understanding lithium thionyl chloride chemistry

Bobbin-type lithium thionyl chloride (LiSOCl2) batteries are ideal for medical applications that require low average daily current along with extended battery life of up to 40 years. Bobbin-type LiSOCl2 cells deliver higher energy density and higher capacity, along with a very low annual self-discharge rate. Typical applications include bone healers, oxygen meters and glucose meters.

Due to the absence of water and the chemical and physical stability of the electrolyte materials, certain bobbin-type LiSOCl2 cells can withstand high temperatures up to 125°C, enabling equipment to undergo routine autoclave or chemical sterilization without having to remove the battery.

A prime example is Awarepoint battery-powered radio frequency identification (RFID) real time location systems (RTLS) that continually monitor the location and status of medical equipment. Environmental tests performed by Awarepoint showed that the bobbin-type LiSOCl2 battery could withstand +135°C temperatures and could work continuously for 500 steam sterilization cycles. The battery was compact, lightweight and powerful, delivering 0.55Ah capacity @ 0.5mA while also being completely safe, U.L. recognized, and considered non-hazardous when shipped.

Bobbin-type LiSOCl2 cells can also be modified to operate at -80°C for use in the medical cold chain, enabling the continuous monitoring of frozen tissue samples, transplant organs, medical supplies, and pharmaceuticals while being transported.

However, be aware that LiSOCl2 batteries are not created equal. A superior quality cell can feature an average annual self-discharge rate of 0.7% whereas an inferior quality LiSOCl2 battery can have an annual self-discharge rate of up to 3% per year. For automatic external defibrillators (AEDs) that can remain idle for years but then need to perform reliably in a life-saving emergency, it makes sense to choose a superior quality bobbin-type LiSOCl2 battery that features the lowest possible annual self-discharge.

Hybrid batteries power high current pulse applications

A hybrid version of the bobbin-type LiSOCl2 cell combines a standard battery with a patented hybrid layer capacitor (HLC) that acts like a rechargeable battery to deliver the periodic high pulses required by external defibrillators.

A similar technique is utilized to create lithium metal oxide batteries that can deliver high voltage and high energy density, along with instant activation and extended operating life, even at extreme temperatures. Lithium metal oxide batteries deliver an open circuit voltage of 4.0 V with high pulses of up to 15A and 5A continuous current at 3.2V for a limited time. Often utilized in hand held surgical power tools and cauterizers, these powerful little batteries enable hand-held devices to become lighter and more miniaturized.

For example, the BioAccess portable small bone drill was powered by alkaline battery pack that performed well and offered excellent reliability. By substituting 6 AA-size TLM-1550HP lithium metal oxide batteries for the alkaline battery pack, BioAccess achieved a 36% weight reduction with only 40% of the volume. An equivalent alkaline battery pack would have required 3X the weight and 2.5 times the volume (15 AA-size alkaline batteries vs. 6 AA-size TLM-1550-HP batteries). Use of a lithium metal oxide battery pack also enabled the surgical drill to deliver faster drilling speeds, more active drill time (30 to 40 seconds at a time for up to 20 to 30 cycles), more instantaneous power, and greater stall torque, resulting in more efficient drilling cycles with less operator fatigue.

Industrial grade rechargeable Li-ion cells

Numerous medical devices are currently powered by consumer grade Lithium-ion (Li-ion) rechargeable batteries. Consumer Li-ion cells have inherent drawbacks, including short operating life (maximum 5 years and 500 recharge cycles, a high annual self-discharge rate (up to 60% per year) and a limited temperature range (0°C to 60°C) with no possibility of recharging or discharging at extreme temperatures.

Industrial grade rechargeable Li-ion batteries are now available that feature up to 20 year operating life with 5,000 full recharge cycles, able to deliver high current pulses (up to 5A) and offering a much wider temperature range (-40°C to 85°C) with the ability to be discharged and recharged at extreme temperatures (10-hour rate).

Industrial grade Li-ion batteries could see dramatic opportunities for growth with telematics and GPS tracking devices being coupled with heart rate, temperature and other advanced sensors used to monitor the health and location of patients in hospitals, nursing homes, assisted living quarters or remotely. These and other emerging medical technologies will benefit from reliable, long-term battery-powered solutions.

Sol Jacobs is VP and general manager for Tadiran Batteries. He has over 25 years of experience in developing solutions for powering remote devices. His educational background includes a BS in engineering and an MBA.