Microcontrollers were one of the hot topics at the Medical Sensors Design Conference, held May 8-9, 2017, in Boston, MA. The relatively simple controllers originally created for embedded applications, have evolved into powerful processors sporting highly-specialized peripherals that make them well-suited for working with the sensors used in medical and fitness products. In his talk “Meeting the Challenges of Sensor Data Processing for Portable, Wearable and Implantable Medical Devices,” Zhang Feng, Senior Applications Engineer at Microchip Technologies, shared several real-world examples of how modern MCUs’ enhanced processing capabilities can be used to process the sensor’s noisy, unreliable signals into accurate biomedical data while sipping a miserly amount of battery power. When we caught up with Mr. Zhang after his talk, he shared a few more insights on using MCUs to get the most out of the sensors used in health and fitness products.

This nebulizer delivers highly-accurate doses of medication, thanks the the embedded MCU that controls it. Images courtesy of Microchip Technology

MDT: How do today’s MCUs differ from the relatively simple microcontrollers originally used in earlier generations of bio-sensing devices?

Zhang Feng: Today’s microcontrollers (MCUs) are more sophisticated and have more functions than ever before. Bio-sensing devices often require a series of electronic interfaces that translate bio-signals from the physical world into the digital world where the measurements are then calculated. For example, our newer microcontrollers, such as the PIC16 family, feature highly-integrated intelligent analog and Core Independent Peripherals (CIPs) which can provide microcontroller-based biometric sensor data acquisition (DAQ) system.

MDT: Can you share a few examples of how these new capabilities are helping to improve the accuracy and performance of the sensors commonly used in wearable health and medical monitoring products?

Zhang Feng: From the new wearable devices to advanced monitors in operating rooms, non-invasive biometric monitoring can use as many as eight wavelengths of LED light to measure heart rate, oxygen saturation, carbon monoxide levels and other factors relevant to a patient under general anesthesia.

The challenge in systems with multiple signal sources is that each LED must share the same photodiode. A traditional pulse oximeter turns on each light source in sequence and then takes each measurement in turn. Every source gets its own slice of time in which the photodiode can get its measurement.

This method is called Time-Division Multiplexing (TDM). This is the same principle used in TDMA-based cell phone systems. The drawback of the TDM approach is that adding more light sources, while keeping the data processing routine the same, results in a longer timeframe to get measurements from every source.

To solve this problem we developed a new technique called Phase Division Multiplexing (PDM). The basic idea is to use a special encoding/decoding scheme to allow multiple LEDs to transmit light simultaneously with only a single photodiode to receive the combined lights, similar to Code Division Multiple Access (CDMA) technology.

To do this, Microchip uses a proprietary PDM technique which is available for our customers to freely use in their Microchip-based designs. To implement the PDM technique in our microcontrollers, we utilize Configurable Logic Cells (CLCs) which is one example of the many Core Independent Peripherals (CIPs) featured in Microchip’s newer 8-bit microcontrollers such as the PIC16 family. The hardware-based CLCs provide programmable logic that operates faster than, and without the limitations of, software execution.

Our study revealed that the PDM results showed about double the peak-to-peak signal amplitude as the TDM results. Adding more light sources had no impact on the measurement period or results of the other light sources. Any noise jumping into the system would never be able to match the reference sequence so that the noise is effectively removed from the system during autocorrelation.

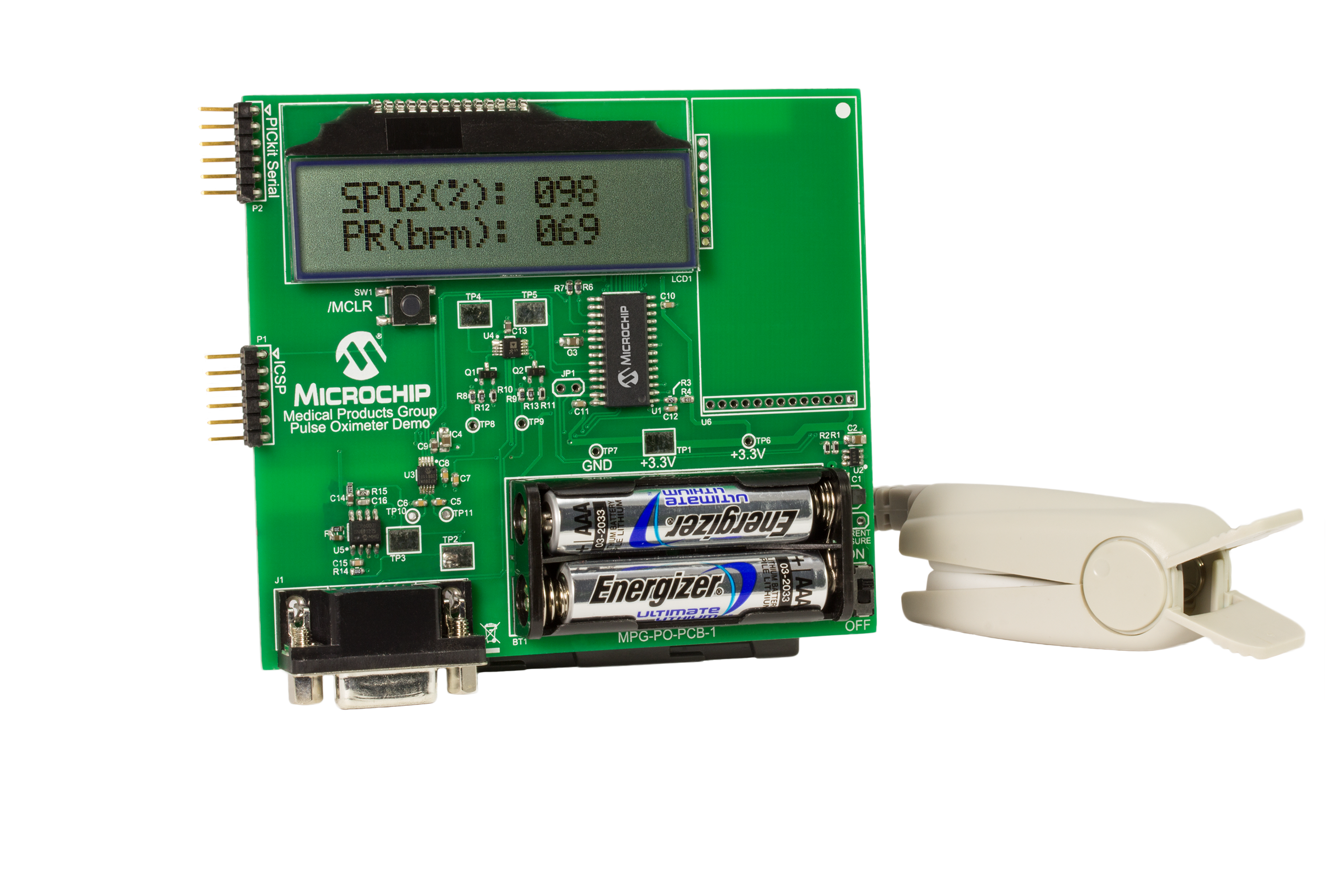

One implementation of this method is our reflective pulse oximeter demonstration board. A single 8-bit MCU is the only chip needed in order to measure heart rate and blood oxygen level on a wearable device design.

MDT: Can you share some examples of how modern MCUs can process the inputs from two or more sensors to produce new types of biometric measurements?

Zhang Feng: The demand for more sensors on wearable consumer and medical designs is increasing at a fast pace. As the amount and quality of biometric data that can be measured on the human body increases there is a corresponding increase in the amount and types of additional biometric data that can be calculated on the device or on cloud servers.

It is becoming commonplace for these types of designs to have multiple sensors to measure things such as proximity, step count, free fall (detection), gyroscopic motion, ambient temperature, pressure (altitude), humidity and light. The capability to do these basic measurements allows for easy development of more advanced functions such as distance travelled, calories burned, sleep analysis, stress, etc.

A reference design for a transmissive pulse oximetry monitor

Using conventional MCU architecture, an Analog Front End (AFE) chip is typically also designed into the circuit to filter out noise and to process the data from the photodiode. However, the challenge in pulse oximeter design is accurately separating true and weak light signals at each of the LED wavelengths from the massive background noise collected by a human body.

By using the digital signal processing capabilities of a DSC MCU the AFE chip can be replaced with two inexpensive op amps and a passive RC filter. We found that by implementing a FIR filter in one of our dsPIC33 DSCs and by using its integrated ADC, a pulse oximeter design can have robust filtering capability, lower component count, lower BOM cost and lower power consumption than a traditional pulse oximeter design.

We have also found a few other advantages for using a DSC MCU for pulse oximeter design. By utilizing DSP techniques we’ve found that we get good noise rejection from fluorescent lighting, finger movement and other noise sources. Reducing these types of noise is critical for accurate heart rate and blood oxygen measurement.

MDT: Are there any commonly-overlooked “tricks of the trade” that can be used to stretch the limited battery capacity of a wearable device’s batteries? (optional)

Zhang Feng: As the demand for more features continues to grow for wearable devices, developers cannot continue to rely on the traditional approach of increasing the number of MIPS, bytes and megahertz for every new function. This approach increases the overall power consumption, cost and physical footprint – all things that designers want to avoid. In order to design for function enablement, many of its traditional tasks need to be offloaded from the microcontroller’s CPU .

A cost-effective method to do this is to use CIPs on the MCU that can operate without supervision from the CPU and that can communicate directly with other peripherals. These types of on-chip peripherals can deliver blocks of function-specific hardware intelligence that require little to no code, consume very little power and require much less RAM and Flash to implement each given function. These CIPs can enable flexible, power-efficient designs with the capability to perform the same tasks as much larger and more expensive MCUs without the added cost, footprint, power consumption or complexity.