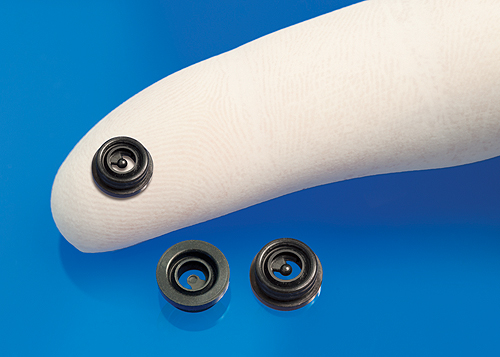

Bi-Directional seals handle opposing pressures while preventing leakage. Custom designs from Minnesota Rubber and Plastics are ideal for a wide range of fluid delivery applications including medical and dental devices.

To make these seals work, Minnesota Rubber and Plastics designed a unique double-lip seal. The lip facing up contains downward fluid pressure. The lip facing down contains the upward fluid (negative) pressure. The seal functions with the squeegee effect of a windshield wiper blade’s alternating motion.

Contributing to the effectiveness of these double lip seals is correct material selection and molding it properly to very tight tolerances. Minnesota Rubber and Plastics uses specially formulated EPDM (Ethylene Propylene Diene Monomer) compounds for certain of its medical applications. Formulated and molded to ensure low extractables, seal materials are compatible with a wide range of fluids prescribed for administration through an IV system.

Seal size is also important in double lip design applications. A smaller seal reduces potential for leaks. Minnesota Rubber and Plastics designs these double lip seals as small as .046 OD, .140 ID and .145 (inch) thickness. Critical surface dimensions for this size are: ID +/- .004, OD sealing diameter dimension (.295) held to +/-.005. Sealing thickness held to +/-.005. To achieve these accuracies, Minnesota Rubber and Plastics utilizes state-of-the-art transfer molding systems that ensure repeatable quality.

Minnesota Rubber and Plastics

www.mnrubber.com

::Design World::