6. ApiJect Systems: $111 million (Drug Delivery)

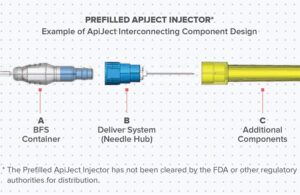

ApiJect designed the Prefilled ApiJect Injector as an inline BFS prefilled syringe. [Illustration courtesy of ApiJect]

The Stamford, Connecticut–based company not only designs the drug delivery systems, but partners with a CMO to fill-finish up to 45 million units per month. ApiJect said its first product submitted for regulatory approval will be its Prefilled ApiJect Injector, which can deliver a 0.5mL dose with just a squeeze of the container.

Founded by Marc Koska and Jay Walker in 2018 to prevent deaths and infections from reused syringes, the company prototyped the first blow-fill-seal (BFS) inline, prefilled injector in 2018. Near the start of the COVID-19 pandemic in 2020, the company worked with the U.S. Department of Health and Human Services on BFS-based drug delivery systems for emergency response and then the Department of Defense on emergency capacity for COVID vaccines.

ApiJect said its May 2022 funding round valued it around $300 million.

“ApiJect is developing an innovative portfolio of drug delivery devices using high-speed BFS manufacturing, which is recognized by the FDA as an advanced aseptic process that forms, fills and seals a single unit dose in a continuous, automated manufacturing step,” the company said in a news release announcing the funding. “BFS technology greatly reduces the risk of contamination and error during one of the most critical steps of drug production. BFS is cost-efficient for short and long runs, and highly suitable to scale quickly in order to meet unexpected spikes in demand such as for a rapid response to population-scale health emergencies. Advancements developed by ApiJect for temperature management now enable BFS manufacturing of a vast array of sterile injectable drugs, including ultra-cold mRNA vaccines.”