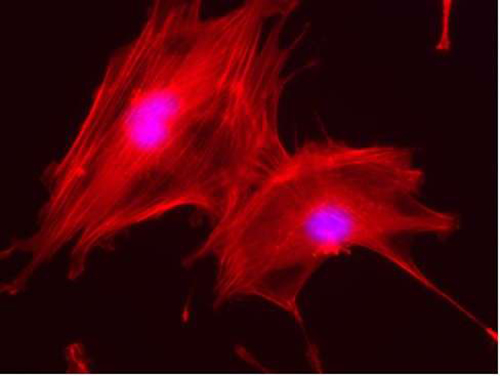

Osteoblast cells of a mouse growing on 3-D matrices and developed from waste of the agri-food industry. (Credit: Milagros Ramos, Ángeles Martín, Malcolm Yates and Violeta Zurdo (CTB-UPM y CSIC))

Researchers from UPM and CSIC have employed waste from the agri-food industry to develop biomaterials that act as matrices to regenerate bone and cartilage tissues, which is of great interest for the treatment of diseases related to aging.

The researchers have produced biocompatible materials from apple pomace resulting from juice production. These materials can be used as 3D matrices for the regeneration of bone and cartilage tissues, useful in regenerative medicine for diseases such as osteoporosis, arthritis or osteoarthritis, all of them rising due to the increasing average age of the population.

Apple pomace is an abundant raw material. The world production of apples was more than 70 million tons in 2015, of which the European Union contributed more than 15 percent, while a half-million tons came from Spain. About 75 percent of an apple can be converted into juice and the remainder, known as apple pomace, contains approximately 20 to 30 percent dried matter, and is used mainly as animal feed or for compost. Since apple pomace is generated in vast quantities and contains a large fraction of water, it poses storage problems and requires immediate treatments to prevent putrefaction.

The procedure of the multivalorization of apple pomace carried out by the UPM and CSIC researchers is based on sequential extractions of bioactive molecules, such as antioxidants or pectin, to obtain the material from which a biomaterial with suitable porosity and texture can be devloped for use in tissue engineering.

The primary extraction of antioxidants and carbohydrates constitutes 2 percent of the dry weight of apple pomace and pectin extraction is 10 percent. The extracted chemical cells have recognized value as nutraceuticals and pectin is a material of great utility in medical applications, such as antitumor drugs or in the treatment of coetaneous wounds.

Furthermore, it has been found that the materials remaining after antioxidant and pectin removal can still confer adequate structure, texture and composition to grow diverse types of cells. In this particular case, the chosen cells were osteoblasts and chondrocytes, both of which are useful for the regeneration of bone and cartilage tissues.

Today, there are expensive products in the market with the same applications, reaching over €100 per gram, while waste used in this work hardly reaches €100 per ton. For this reason, there are consistent incentives to convert this waste into final products of great added value.

According to Milagro Ramos, a contributor to the study, “With this approach, we achieve a double goal—using waste as a renewable raw material of high value and chemical diversity, and secondly, reducing the impact of waste accumulation on the environment.”

Thanks to the new materials obtained in this work, researchers are developing new technological applications that allow them to structure customized biomaterials through 3D printing techniques.