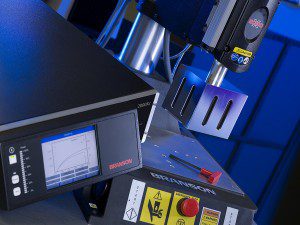

Branson Ultrasonics says its ultrasonic assembly system enables secure electronic records management and parts traceability.

Branson Ultrasonics, a business of Emerson, introduced a new addition to its 2000X series of Ultrasonic Assembly Systems at the National Plastics Expo.

The new 2000Xc ultrasonic welding system combines consistent high quality welds with the process control needs of today’s manufacturing environment. The 2000Xc locks in the welding process with fully electronic welder settings, hierarchical password protection, and Ethernet connectivity access.

The system offers secure process controls and detailed weld data to meet the global compliance, traceability and security needs of today’s medical, automotive, business and consumer electronics markets. The security feature helps to ensure compliance with medical manufacturing regulations, including ISO 13485 and FDA 21 CFR part11.

The Branson 2000Xc can be adapted to automation systems or as a stand-alone complete system in an assembly cell.

Among the features on the new system are:

- The capability to weld by time, energy, peak power, ground detect, collapse, or absolute

- Electronic programmable weld pressure, hold pressure, down speed and rapid traverse

- Process change audit trail

- No operator accessible controls – ensuring validated processes remain unchanged

- Total Ethernet access via web services

- USB barcode for recording part Unique Device Identification

- Storage for 100,000 weld result histories and 1,000 weld presets

- Full VGA touch screen with four levels of assignable password hierarchy

- Three frequencies: 20, 30 and 40kHz

Emerson

Emerson.com

Branson

www.BransonUltrasonics.com