[Image from the researchers]

The team of researchers made an advanced version of Freeform Reversible Embedding of Suspended Hydrogels (FRESH) technology in order to 3D print collagen with complexity to construct components of the human heart. The method spans from small blood vessel to valves and beating ventricles. The FRESH technology was recently awarded a U.S. patent and is being licensed to FluidForm.

“We now have the ability to build constructs that recapitulate key structural, mechanical and biological properties of native tissues,” chief technology officer and co-founder of FluidForm Adam Feinberg said in a press release. “There are still many challenges to overcome to get us to bioengineered 3D organs, but this research represents a major step forward.”

Organs, tissues and implants have seen innovations in 3D printing in recent years, but 3D bioprinting has its obstacles. Soft and dynamic biological materials need to be supported during the printing process in order to get the resolution and fidelity needed to recreate complex 3D structures and functions, according to the researchers.

FRESH is an embedded printing approach that uses support gel that allows for complex scaffoldings to be 3D printed using collagen in its unmodified form. Researchers have previously seen limitations because soft materials are harder to print with high fidelity past a few layers in height because it will sag.

To overcome the obstacles, the research team developed an approach that uses rapid pH changes to drive collagen self-assembly.

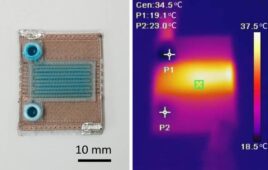

The FRESH 3D bioprinted heart components were based on human MRI images and accurately reproduced patient-specific anatomical structure. The smaller cardiac ventricles were printed with human cardiomyocytes and showed synchronized contractions, directional action potential propagation and wall thickening up to 14% during peak systole. The researchers still have challenges to address in generating billions of cells that are needed to 3D print larger tissues while manufacturing on a larger scale and overcoming the regulatory process for clinical translation.

The researchers say that the human heart was used as a proof-of-concept, but suggests FRESH printing of collagen and other soft biomaterials has the potential to build advanced scaffolds for a wide range of tissues and organ systems.

“FluidForm is extraordinarily proud of the research done in the Feinberg lab,” CEO Mike Graffeo said. “The FRESH technique developed at Carnegie Mellon University enables bioprinting researchers to achieve unprecedented structure, resolution and fidelity, which will enable a quantum leap forward in the field. We are very excited to be making this technology available to researchers everywhere.”

FluidForm plans to commercialize the FRESH technology through its LifeSupport bioprinting support gel.