Cracking of polymer housings for medical equipment is a growing concern among designers. The cause of this problem is environmental stress cracking. PolyOne released a white paper on the topic in 2014, examining the causes of cracking as well as assays on the materials that can resist the stresses.

Cracking of polymer housings for medical equipment is a growing concern among designers. The cause of this problem is environmental stress cracking. PolyOne released a white paper on the topic in 2014, examining the causes of cracking as well as assays on the materials that can resist the stresses.

Essentially, says the paper, increased use of chemical disinfectants in hospitals is the source of this cracking. Recommended cleaning for equipment such as patient monitoring devices, infusion devices, dialysis equipment, respiratory devices, defibrillators, and handheld devices, is after every new patient. The frequency of cleaning and move to harsher chemicals is in response to antibacterial-resistant MRSA and other hospital acquired infections (HAIs). The irony is that the process can also increase the brittleness of some polymers. Once embrittled, polymers can develop small microfractures or crazing. This crazing leads to larger cracks and eventual fracture of the housing. Different chemicals can affect a polymer in different ways. A polymer can be resistant to one chemical but easily crack when exposed to another chemical.

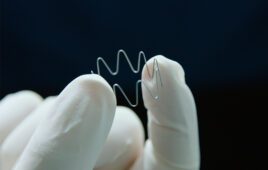

This problem is still being seen in hospitals. The most recent example is Cook Medical, which recalled all lots of catheters using its Beacon Tip locating technology. The polymer used by Cook in the catheters was unable to withstand the “whole room sterilization procedures” used some hospitals.

And according to PolyOne, choosing a polymer that resists these powerful disinfectants is a key method to eliminate the cracking issues. PolyOne conducted laboratory work to study how various polymers withstood various disinfectants. The materials were tested with several disinfectants found to be effective against MRSA and VRE including T-SprayTM, CIDEXPLUS, and CaviCide.

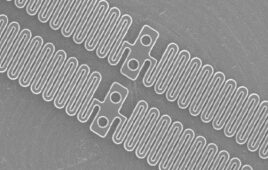

The set up for the study started with bars of five different polymers used commonly in medical equipment housing. These bars were bent into the apparatus to create stress in the middle of the bar. The disinfectant being tested was placed on a porous cloth and put into continuous contact with the bar for 3 days. Tensile properties of each polymer were tested before and after exposure. Polymers with 90-100 percent property retention were classified as “Acceptable,” 50-90 percent as “Marginal,” and less than 50 percent as “Poor.” Polymer samples that cracked before the three-day testing period was completed were also identified.

The results showed that only rigid vinyl performed as “Acceptable” for all three disinfectants. PC+PBT performed as “Marginal” for the three disinfectants. FR ABS, PC+ABS, and PC+PET performance ranged from “Cracked” to “Marginal.” Of the three disinfectants trialed, T-SprayTM appears to be the harshest on polymers while CaviCide appears to be the mildest, only having a significant affect on FR ABS.

Researchers concluded that medical equipment manufacturers should consider rigid vinyl as a material of construction if polymer cracking is a concern in the application.

It is worth noting that in the Cook Medical situation, it was not disinfectants, per se, that caused the problem, but rather, as Cook Group president Pete Yonkman explained to MassDevice, “We were starting to see that these customers were using technologies that were trying to sterilize their ORs. They were using technologies like UV, high-intensity UV. Some were using vaporized hydrogen peroxide, [at] high temperature.”

This indicates that although hospitals are taking rightful precautions to prevent the spread of HAIs, there may be unintended consequences. OEMs with products that contain polymers subject to sterilization treatments should adopt a watchful eye.