Whether you are an inventor, small company, or large original equipment manufacturer, you have a high probability of needing a plastic component that you cannot manufacture yourself. Even large companies do not necessarily have in-house capabilities to injection mold all of their own products, or have experience in all resin and processes that they may need. It is at this point that companies turn to custom injection molders. Do you know what information the custom injection molder requires or examines when they start their internal process to supply parts to you? Hopefully, the following will answer some of those questions for you.

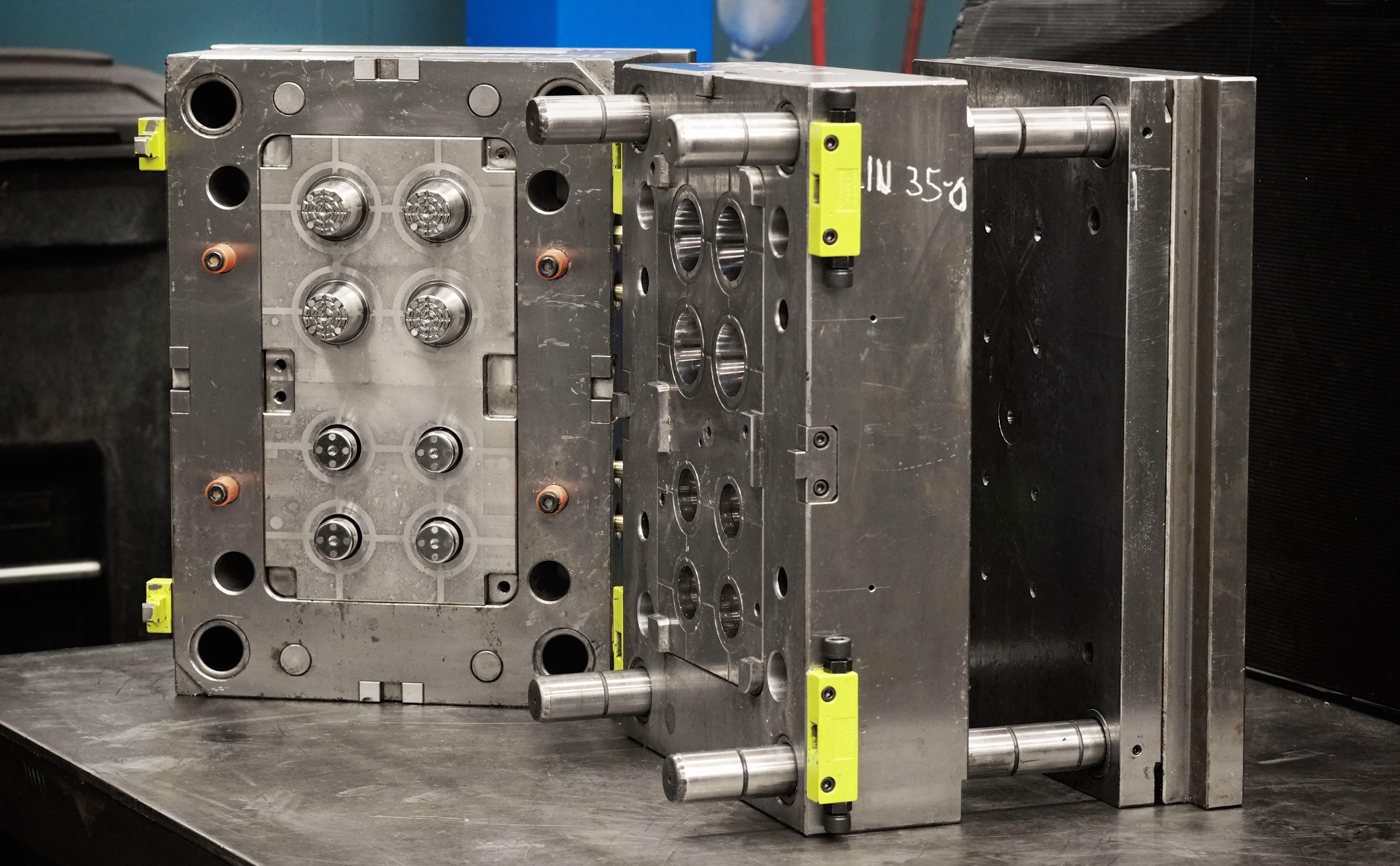

The first question asked is if the project is completely new or if molds exist and are just being transferred from a current source. Transfer molds do not require new tooling to be built, but they offer another set of challenges. The molder will want to know everything they can about the current molds. The basic information includes cavitation, size of the mold, and any processing information. These will be needed to ensure that the right equipment is available to run the product, but also to provide an accurate quote. Transferring tools always causes at least some anxiety due to the unknown. Customers may believe they own a mold, only to find out that they own some plates or inserts, or worse yet, don’t own anything. The molds may also need to be modified to fit the new molder’s equipment.

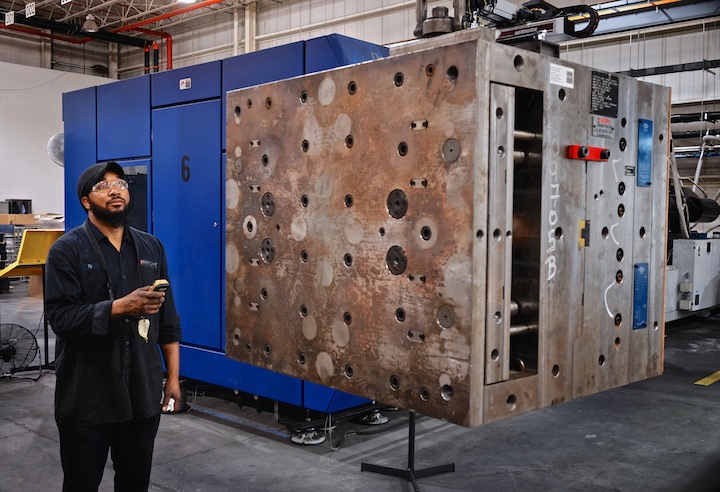

(Credit: Bright Plastics)

Equipment can and will vary from one injection molder to the next.

If the project is brand new, tooling will need to be built. The customer must decide if there are any limits on where the mold can be built. Molds can be made locally or globally. Price may drive the mold to be built offshore, but technical requirements or concerns about intellectual property theft may require the mold to be built in North America or Europe. Before the mold is built, the customer may want to have prototypes made. 3D printing is a very useful tool today and 3D printed parts can be produced quickly and economically. Other testing requirements may require that an actual prototype mold be built. These requirements should be established before a production tool is quoted so that time is not wasted quoting production tooling when major changes may occur once prototypes are examined.

To build 3D models, the part must exist in 3D. Molds can still be built from 2D prints but almost all mold builders will build a 3D model from the 2D prints before they start to construct a mold. This cost will be included in the mold cost. The most common users of 2D prints today are quality departments. Control plans are based on the critical dimensions that are specified on 2D prints and the 2D print is what is used as a visual reference. So, if a 3D model does not exist, a designer or engineer must take the time to build one. SOLIDWORKS® is a common software package that is used in the plastics industry, but any software that can produce files in the “.stp” format can be used.

Resin selection can be a complicated process. There is a plethora of different plastics and blends of plastics in the market. Different plastics exhibit vastly different properties and adding components such as glass, carbon fiber, cellulose, or talc can drastically change the base resin’s properties. Plastic properties are also generally a give and take. If one property is increased, another will almost assuredly decrease. Even though custom injection molders work with plastics every day, the plastics experts are really the resin manufacturers. For extremely difficult applications, expect the injection molder to work with resin suppliers to specify the exact resin that is needed. If the resin is already specified, then the injection molder will merely locate the manufacturer or distributor and source the resin.

The injection molder’s quality department will be involved very early in the mold building process. They will want to communicate directly with the customer so that a control plan can be established. Quality personnel will want to know what dimensions and properties are critical to the part’s function and which are not. This is crucial to not only part acceptance, but also to processing the part. If the part is cosmetic and surface finish is crucial, processors will focus on this property as they produce the parts. But if the part is hidden from the ultimate customer’s view and surface finish is not important at all, processors will not spend extra cycle time and effort eliminating something that is not required. The customer will needlessly pay for that extra time and effort in cycle time if it is not known that it is not important. Quality personnel will also need to know if any special testing will need to be developed, equipment sourced, or an outside laboratory located. All of this should be done while the mold is being built so that it is complete before the first parts are manufactured off the mold. Initial samples can then be used to verify any testing methods or equipment well before the actual validation begins.

Custom injection molders work with packaging requirements that range from parts packaged in a plain brown corrugated carton to full retail packaging. While the former is relatively simple, the latter can get very detailed and complicated. Shipping directly to major retailers can require retail packaging with labels, instruction sheets, master cartons and pallet labels. Major retailers also have shipping tests that must be performed, detailed delivery schedules, and incur penalties if any of the above are not followed correctly. Packaging can take a couple of minutes to establish or weeks to source and test.

(Credit: Bright Plastics)

The final details that need to be resolved are the finer details of the relationship. If the molder is making heavy investments in capital equipment, they will most likely want a contract for a period of years. If not, then a supply agreement may be sufficient. The agreement should detail the stocking levels required and responsibility of both the molder and the customer, regarding this inventory. Ordering patterns and payment terms will also need to be in the agreement, as well as any other items that are specific to the product or the customer.

Every project is different, but everything we’ve covered here needs to be discussed on every project. Customers approaching custom injection molders should be prepared to answer these questions to the best of their ability and understand where there is some ambiguity. They should not be surprised when quotes are provided with contingencies based on these ambiguous areas. While this can be frustrating at times, paying attention to these details will help insure the successful realization of your design.

(Credit: Bright Plastics)