Superfeet, the leading maker of over-the-counter insoles for the active lifestyle and outdoor markets, has built its brand over four decades of unrelenting focus on stabilizing the foot while providing unparalleled support and comfort. Today, the company is able to draw from its extensive expertise in “foot shape” to produce custom insoles that deliver optimum performance. But Superfeet also constantly looks ahead to leverage next-generation technologies to deliver its products in a more efficient, effective and personalized package.

This is what led the company to consider how the emerging field of additive manufacturing – aka 3D printing – might further its mission to deliver the Superfeet shape to its customers. Additive manufacturing, in theory, offered Superfeet the ability to convert a customer’s foot shape into a digital data that could be stored, transmitted and tailored to a custom insole that could then be printed on any networked machine. With 3D printing, even lot sizes of one are cost-effective. The possibilities offered represented a radical leap forward in Superfeet’s mission and, if successfully leveraged could upend its supply chain and revolutionize the company’s business model.

There was only one problem. The company knew nothing about designing for 3D printing, much less leveraging it as a medium for manufacturing and delivery. In general, 3D printing is used to develop prototypes, not finished products. It can be slow and expensive, compared to high-volume injection molding. Before Superfeet could take its first step, it needed a partner that was well-versed in design, manufacturing and delivery, which is what led the company to Jabil – a a design and manufacturing services, and supply chain management partner that supports companies at every stage of product development.

Superfeet insoles come in every color of the rainbow and may be customized to everyone’s unique shape. (Credit: John Dulchinos)

The Four D’s

Superfeet engaged Jabil’s proven methodologies in “design for manufacturing” though the “gateway” of its Radius Innovation and Development business, which maintains studios around the world. Radius’s role within Jabil is to help customers bridge the initial gap between ideation and commercialization of their product ideas. To do this, Radius’s inter-disciplinary teams apply a process known as “The 4D’s,” which covers four phases: Discover, Design, Develop, and Deliver.

During the Discover phase of the Superfeet project, Radius didn’t just come up with ideas – it also eliminated them. This required establishing criteria for defining success, identifying the key variables leading to success and guiding Superfeet’s concept from its high-level business goals through its specific technical requirements. Much of the Discover phase also involved determining whether what Superfeet wanted was technically feasible. This included an analysis of traditional and additive manufacturing techniques, and the exploration of compatible materials and adhesives with specific properties.

By guiding Superfeet through the Discovery phase, Radius not only helped to define the rules for making custom 3D printed insoles, but for making them in a commercially successful way. It did this through an iterative process of asking broad questions, narrowing the choices deciding next steps and then asking broad questions again. Over time, Jabil and Radius worked closely with Superfeet to move beyond questions to answers intended to save the insole manufacturer time and money.

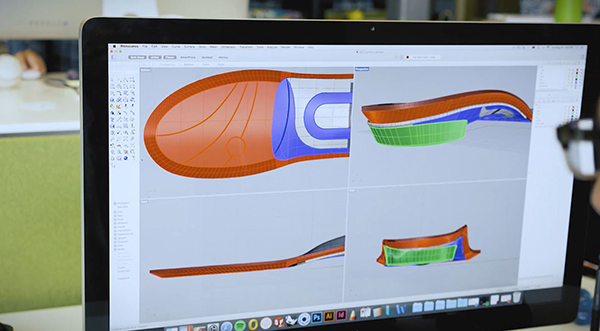

Through its design methodology, Jabil’s Radius team helped Superfeet define what “custom” meant to them, which led them to determine that only parts of the insole required a “customized” solution. (Credit: John Dulchinos)

Beyond Ideation

When Superfeet engaged Radius, the insole manufacturer was just starting the ideation phase of product development. The insole-maker had identified the business requirements for custom insoles, but had yet to invent the process for making them. Through its design methodology, Radius helped Superfeet define what “custom” meant to them, which led them to determine that only parts of the insole required a “customized” solution. Ultimately, the team realized that the entire insole didn’t need to be 3D printed. Instead, Superfeet could still produce a highly customized insole using 3D printed shapes that were inserted between injection-molded insole layers.

Superfeet had already defined the requirements for how it would scan a customer’s foot, which enabled Radius to focus on the specific geometries in different parts of the foot. Jabil also contributed to the team’s Discover phase by researching the availability of materials that could meet Superfeet’s requirements. It narrowed several candidate resin technologies down to a material that offered the right durometer and that supported the use of adhesives. Jabil further determined that compression set and durability were important criteria too, but physical appearance was not. Unlike the components for a wearable device that’s visible on the arm or the wrist, Superfeet’s 3DP printed shapes would be underfoot, between insole layers, and out-of-sight. This supported a strong focus on shape, material complexity and mechanical properties rather than aesthetic requirements. Jabil’s “design for additive manufacturing” expertise also encompassed an understanding of which 3D printing technologies could

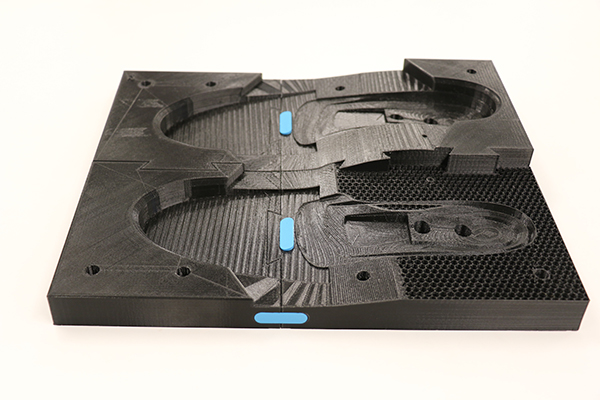

3D-built tooling enables Superfeet to drive down costs and cut time to market for its market-leading insoles. (Credit: John Dulchinos)

D is for Different

Radius’s 4D’s process model provides room to address customer-specific needs. Where the Discover phase defines what success looks like, it’s the Design phase that identifies key variables that will inform development and delivery. Because of its unique integration with a leading manufacturing expert like Jabil, however, Radius brings particular expertise in designing for manufacturability – and that includes additive manufacturing processes.

By working with Jabil and Radius, Superfeet determined that cost, portability, ease-of-use, brand alignment, and color were the most important variables in achieving its goals. Technical performance, safety, and compliance with regulatory requirements mattered, too. The approach the team used to establish these variables was pragmatic, and required Superfeet to ask and answer questions in a structured way. “The boss wants it this way” may not be a technical requirement, but it is a business requirement that may need to inform product design. Balancing different requirements, such as cost vs. brand alignment, is also imperative.

During the next “D” phase – Develop – CAD data from Superfeet helped the team produce over 40 different prototypes in quantities ranging from 5 to 50. After each run, the builds were compared both to the machine inputs and to Superfeet’s success criteria. As part of this process, Jabil and Radius experimented with multiple configurations to determine the most effective setup for additive manufacturing. The technology doesn’t require tooling charges. But it did require careful balancing of material properties, process control and speed in order to make additive manufacturing a better choice than traditional injection molding in this case.

For example, in order to produce 3D printed prototypes, the team sampled several different grades of a tough, accurate, and bondable engineering resin, as well as multiple adhesives. Superfeet’s engineering expertise helped to inform the adhesive selection process. After the team assembled the 3D printed shapes were assembled the layers of insoles, it tested each model occurred. This process was more empirical rather than analytical, but testing confirmed that the mating geometries were correct. Importantly, the adhesive bonds were so strong that they could withstand being pulled apart with a pair of pliers.

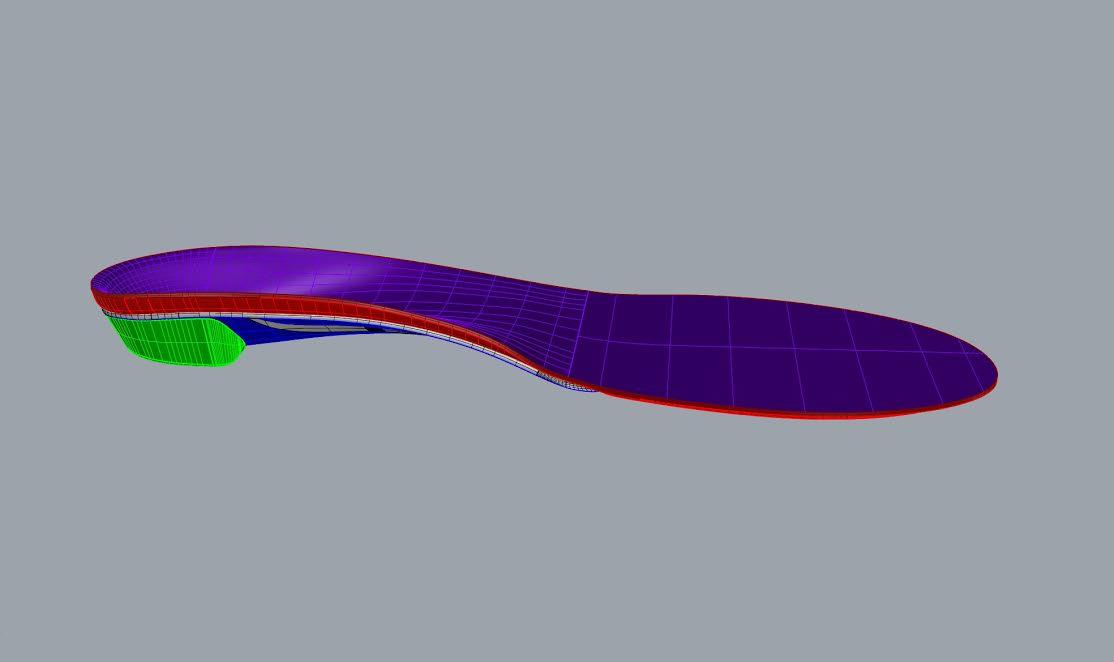

Innovation in 3D enables Superfeet to customize insoles on demand for customers seeking form fitted shapes just for their own feet. (Credit: John Dulchinos)

Running at Full Speed

Prototyping successes are important, but what matters most with additive manufacturing is the ability to create a repeatable, scalable process. Traditional manufacturing methods like injection molding are well-understood, but additive manufacturing is still new enough to encompass some important unknowns.

Today, Superfeet continues to work with Jabil and Radius in making strides towards personalized insole manufacturing. With continuing advances in AM, Superfeet can see the day when 3D printers in shoe stores provide hyper-localize production. At the same time, by leveraging Jabil’s global manufacturing services and supply chain strength, Superfeet can make strides with regard to high-volume manufacturing and scalability.

Despite this, in just four months, Jabil and Radius proved how 3D printing could produce Superfeet’s custom insoles more quickly, efficiently and cost-effectively. Through their collaborative and iterative, design for manufacturing process, they helped Superfeet establish that additive manufacturing alone need not produce the entire insole. Instead, Jabil and Radius applied a combination of 3D printing and subtractive manufacturing to cut the time-to-market for Superfeet’s insoles by more than half. Cycle times and R&D costs were slashed, too. Today, Jabil continues to work with Superfeet to meet its dual demand for high-volume production and custom manufacturing. Moreover, because Jabil can extend its 3D printing expertise to support Superfeet retailers, it continues to explore the final “D” – Delivery – by exploring how highly customized insoles can be measured, personalized and printed on-site while customers wait at their local retail store.