The positioning system with movable lasers “SERVOLASER tireXpert” is equipped with diode lasers with a tested service life of 30,000 operating hours.

The laser specialist LAP offers tire manufacturers future-safe solutions for quality assurance that convince in their durability and integration properties. The positioning system with movable lasers “SERVOLASER tireXpert” is equipped with diode lasers with a tested service life of 30,000 operating hours.

Moreover, with Ethernet/IP, PROFIBUS und PROFINET, the system covers the most common standard interfaces worldwide. This enables existing customers as well as new users a flexible, uncomplicated and cost-effective integration.

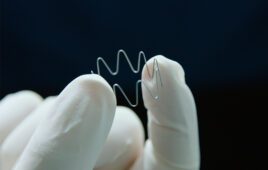

Diode laser with a service life of 30,000 operating hours and optimum visibility

Tire manufacturers that are planning a conversion of their system, or a new investment, profit from the durability of the integrated diode technology with which LAP equips all line laser and laser projectors.

Diode lasers have an approximately threefold higher service life than conventional DPSS laser modules. Long-term tests from LAP confirm an operating time of the diodes of 30,000 hours. For customers, this means an even higher reliability during production and investment security at the same time.

After all, as a result the operating costs are also reduced. The decisive benefit especially with the green diodes is the excellent visibility of the laser lines projected. The full dark green colour tone of the diode laser is perfectly perceptible, especially on dark surfaces, such as the rubber layers of tires.

More flexibility with the integration thanks to the variety of interfaces

With EtherNet/IP, PROFIBUS and PROFINET, the SERVOLASER tireXpert also supports the most widespread communication standards on the market. The positioning system can easily be connected and controlled using the programmable logic controller (PLC) through the standard interfaces.

Further interfaces are available on request. Thanks to the multi-connectivity, the SERVOLASER tireXpert can be used with almost all available PLC systems on the market (e.g. Allen-Bradley/Rockwell Automation ControlLogix controller, Siemens SIMATIC S7 or Bosch Rexroth IndraLogic). LAP therefore offers users the highest possible flexibility when connecting to the machine controller and thus the seamless integration into their production.

Future safe and cost-effective solutions for tire manufacturers

SERVOLASER tireXpert has been established as standard for quality assurance in the tire production for many years in order to visually check the application of the rubber layers on the tire building drum.

“SERVOLASER tireXpert systems are being used successfully at leading tire manufacturers worldwide and are completely integrated in the tire building machines. Many customers however, are faced with the task of converting their machine controllers. LAP has responded to the current demands and provides different interfaces,” said Caren Lüdemann, LAP Sales Manager for SERVOLASER Xpert.

Additional hard- and software are not required. This keeps the system complexity low and saves costs.

“We offer state-of-the-art systems in order to provide optimum assistance for existing customers as well as new customers that want to implement new systems, today and in the future,” said Lüdemann.

Precision, integration, variant diversity: All requirements are covered

The SERVOLASER tireXpert meets all customer-specific requirements in tire building: different positions and sequences of movement can be programmed for individual work steps via the PLC. Even the brightness of the laser line projected as well as the movement speed can be set individually.

Moving ranges up to 2.60 m for OTR tires (off-the-road tires) are covered—and that being with a projection accuracy of up to +/- 0.2 mm.

“LAP laser systems do not only convince with their LAP certified projection accuracy and variant diversity. The support of the most common fieldbus standards worldwide makes the product to a preferred solution, especially in tire building,” said Ralf Müller-Polyzou, head of marketing and product management.

Tested by independent institutes—Technical white papers provide assistance

In order to assist the user in the best possible manner when connecting the SERVOLASER Xpert to the PLC, LAP works together with independent programming experts in the area Connectivity.

Moreover, LAP has prepared technical white papers together with research institutes. These give a practical assistance for commissioning and programming the positioning system.

LAP GmbH Laser Applikationen

lap-laser.com