CerMet – an advanced ceramic and metal technology system – creates the potential for implantable devices with thousands of electrical channels. Think new options for treating blindness and neurological conditions.

Only a few years old, Heraeus’ CerMet is upping the game when it comes to sophisticated implantable electronic devices.

“Medical implants manufactured using the Heraeus CerMet technology can be smaller, more efficient and capable of integrating more functions,” Jens Troetzschel, VP of advanced technologies at Heraeus (Hanau, Germany; St. Paul, Minn.), told Medical Design & Outsourcing. “We can now utilize extremely fine circuit paths that are only 0.15 mm thick, as thin as a piece of paper.”

We asked Troetzschel to explain CerMet and the medical device advances it’s enabling; the following is an edited transcript of our conversation:

MDO: What exactly is Heraeus CerMet technology?

Troetzschel: The Heraeus CerMet material is a strong, high-density and extremely robust ceramic and metal (CerMet) composite of tiny platinum and aluminum oxide particles. But ceramic and metal typically do not bond chemically. To manufacture a feedthrough, until now, individual wires were inserted manually into the ceramic and soldered with a high-temperature process, which is labor intensive and time consuming. However, when many electrical channels are needed, this process quickly reaches its limit, which prevents the development of sophisticated miniaturized devices applied in novel therapies. With CerMet it is possible to realize a density of more than 5,000 electrical channels per square inch, which is a substantial improvement compared to current technologies – and this is not the end of the development.

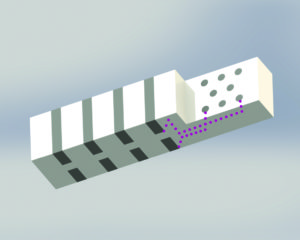

This CerMet technology offers developers and manufacturers of implants greater flexibility in designing new devices because the material system allows for the production of more complex three-dimensional structures. In the area of feedthroughs, it will now be possible to manufacture angled or branched circuit paths, thereby allowing unprecedented design flexibility for the medical implants of the future.

Heraeus CerMet micro-component with internal routing to simplify the design of medical implants e.g. implantable sensors (Image 1)

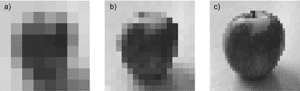

A future retina prosthesis, for example, could be equipped with a significantly increased number of channels, conveying signals from the implant to the optic nerve, which results in improved imaging.

MDO: Where is CerMet being used already?

Troetzschel: We have entered into various partnerships with leading companies and research teams to develop next generation micro-implants. For example, Heraeus is now working with research teams on new interactive micro-implants for the treatment of tinnitus, functional disorders of the gastrointestinal tract, and multilocular muscle stimulation in the field of bionic implants as part of the [five-year, €13.5 million] INTAKT innovation program, which is sponsored by Germany’s Federal Ministry of Education and Research (BMBF) and led by the Fraunhofer Research Institute. This network of medical industry, research, science and clinics is now developing new interactive micro-implants to improve therapies for numerous medical issues and therapies. The INTAKT Program is using the Heraeus CerMet technology to enable a significant miniaturization of novel medical devices.

This program allows us to fine-tune our technology even more, and the close cooperation with medical professionals leads to a much deeper understanding of clinical needs.

Within the scope of technology studies, we developed technologies to connect Heraeus CerMet components to electronic circuit boards on the inside of medical devices and to lead wires on their outside.

Heraeus currently is developing technologies for the integration of CerMet composites in titanium housings. We are also working with numerous medical device manufacturers worldwide to develop next generation enabling solutions in the fields of neuro stimulation, retina implants, hearing aids and implantable sensor applications.

Higher channel count can give better resolution e.g. to improve the performance of next generation retina implants. (Image a) shows an 8×8 grey scale picture of an apple, illustrating a retinal implant with 64 channels, b) shows a 16×16 resolution equaling 256 channels, c) shows 36×36 channels equaling 1296 channels.) (Image 2)

MDO: What is the future of CerMet?

Troetzschel: In general we see a major shift in technologies ahead of us.

Mathematicians and programmers have developed powerful algorithms and software to analyze huge amounts of data to derive information. We’ve got the computational power to handle these huge amounts of data in real time in this day and age. Neuroscientists and researchers are getting a better and more refined picture of the processes that happen in the human body.

All this happening in parallel at the same time creates an enormous momentum which is used by an entirely new group of players in the field of medical devices. Elon Musk’s Neuralink is an example, as well as Apple’s and Google’s activities in this arena.

However, these innovations will require implantable, miniaturized devices able to interface with the nervous system or more generally with the tissue of the human body – and they will have to sense certain bio-signals (biomarkers), process the data and/or transmit to systems outside of the body – which will display the information to doctors or directly to the patients.

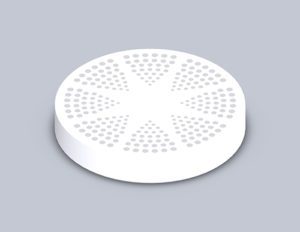

Example of a high channel count feedthrough element

to enable high resolution therapy e.g. for retina implants. (Image 3)

Heraeus CerMet technology can open entirely new design options for significantly miniaturized devices. At the same time, the CerMet technology can allow for a virtually unlimited number of communication channels to interface with the body, and thus can help feed this enormous appetite for data.

As a biocompatible and bio-stable material technology system, CerMet will serve as a means for encapsulation of tiny little sensors or stimulators – which can in combination with flexible electrodes be placed everywhere in the human body, exactly at the point where the signal should be sampled or stimulation is needed.

Hundreds of channels will be used to feedthrough signals in retina implants as well as in brain readers or wearable general purpose recorders for neuro signals – just everywhere where a higher resolution yields a better “picture.”

CerMet will enable a new quality of delivering the therapy to exactly the right point.