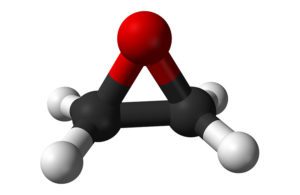

Model of an ethylene oxide molecule.

This article has been updated with a comment from the trade group AdvaMed.

The FDA today announced steps it wants the medtech industry to take to reduce its reliance on ethylene oxide (EtO) as a sterilant.

Based on testimony it received at a recent advisory panel meeting on the sterilant gas, which the EPA considers carcinogenic, the FDA is recommending that medtech companies reduce the amount of paper (such as the labeling and instructions for use manuals) included in a sterile device package and move to delivering that information electronically. A large amount of paper in an EtO sterilization chamber hinders the gas getting to the device and results in higher EtO usage, the agency explained. The FDA said it is working with medtech manufacturers to make the switch where feasible and safe for patients.

To prevent and alleviate device shortages brought on by the EtO crisis, the agency also said it would expedite approvals of certain changes that medtech manufacturers make to ethylene oxide sterilization methods, processes and facilities. Currently, the FDA requires manufacturers that want to change sterilization methods, processes or facilities to submit a premarket authorization (PMA) supplement before they can make those changes. “However, considering the recent sterilization facility closures and concerns about their impact on medical device availability, we recognize the need to facilitate timely process and site changes that may reduce the amount of ethylene oxide used and minimize the impact of supply interruptions,” the agency said in a statement today.

The FDA also announced a two-pronged, voluntary pilot program — one for sterilization facilities and one for device manufacturers. The Ethylene Oxide Sterilization Master File Pilot Program asks facilities that sterilize devices in a chamber to submit a master file when switching to a different site or when making certain changes to processes that use reduced EtO concentrations.

A master file submission provides the FDA with confidential detailed information about establishments, processes, or articles used in the manufacturing, processing, packaging and storing of medical devices. A master file itself is a reference document that the agency uses to evaluate several applications for different products that may use a common material or process, such as the same sterilization method.

The second part of the pilot asks manufacturers and sponsors of Class III (high-risk) devices affected by such sterilization facility changes to reference the master file submitted by their sterilization provider in a post-approval report, rather than in a PMA supplement. Then new reporting method would expedite the process, the agency said. Details of the program are scheduled for publication in the Federal Register on Tuesday.

“By facilitating more efficient review and feedback, this pilot program should also result in sterilization facilities using a reduced amount of ethylene oxide several months sooner than they otherwise would while still providing robust patient safeguards,” the FDA said. “Consequently, we believe this pilot program will allow more nimble response to sterilization site closures by more quickly approving sterilization site relocations and speeding up the implementation of sterilization methods that reduce the amount of ethylene oxide needed to sterilize PMA-approved medical devices. This could reduce the impact of ethylene oxide on the environment and on the public health while at the same time continuing to ensure patient access to safe medical devices.”

The agency also said it had selected 12 of 46 applications it received for a pair of challenges it issued in July to find alternatives to EtO as a sterilant and to reduce emissions of the carcinogenic gas. The selected entries cover sterilization by nitrogen dioxide or vaporized hydrogen peroxide, reduced sterilant concentration and the use of ethylene oxide-flexible chamber technology. The agency said it will work directly with the 12 applicants to accelerate the development and review of innovative technologies for sterilization processes.

Medtech trade group AdvaMed said it appreciated the FDA’s efforts to tackle the ethylene oxide issue.

“AdvaMed supports the agency’s proposal to pilot the use of master file submissions for changes to sterilization sites and/or processes and to encourage greater use of electronic materials to replace paper materials in sterile packaging,” an organization spokesman said in an email to Medical Design & Outsourcing. “FDA has repeatedly acknowledged, most recently at their advisory committee meeting earlier this month, the public health crisis that would occur if current EtO sterilization capacity were to be further curtailed, and we look forward to working with the agency to ensure the continued availability of safe, sterile and effective medical devices. The medical technology industry is committed to the continued safe and responsible use of EtO, while simultaneously exploring ways to lessen our EtO footprint and to using alternative sterilization methods when they are proven to be as safe and effective.”