The ability to individually control carriers of a conveyor system delivers the customer-desired feature of flexibility in automated assembly systems. Systematix Inc., which designs and builds turnkey factory automation systems for demanding industries including pharmaceuticals and medical devices, needed to find a way to develop a flexible automation system for one of its customers, a company prominent in the medical device industry. Engineers increased flexibility in the new, fully automated assembly and inspection system for a single-use specialty medical device containing a needle and vial with the help of MagneMotion’s MagneMover® LITE (MM LITE™) Intelligent Transport System.

The end customer was already manufacturing this device and needed a second production line for additional capacity. The assembly process consisted of several steps, including mechanical assembly, adhesive application and cure, and robotic placement into packaging at the end of the line.

The customer’s requirements for the finished system included:

- Reliably assembling an intricate product accurately and consistently

- Performing automated inspection of components and in-process assemblies with rejection of nonconforming parts

- Maintaining a 2.5 second cycle time

- Operating inside an ISO 7 (Class 10,000) clean room

- Assembling at least two devices in the product family without significant changeover time or labor input

- Minimizing the capital outlay

- Minimizing operating costs by reducing labor to a single operator, and minimizing scheduled maintenance and spares requirements

- Minimizing cost and effort required for validation of the process

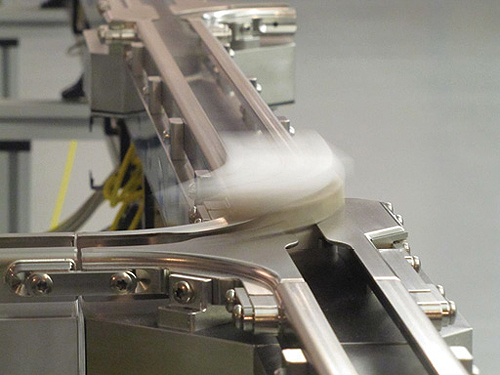

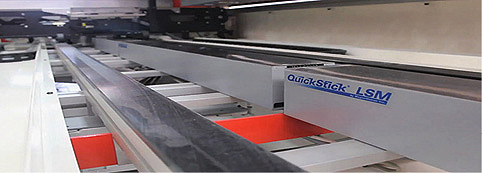

The MM LITE system consists of individual carriers (pucks), the guide-way they run on, and the electronics that control their motion. The system uses linear synchronous motor technology. A linear synchronous motor is similar to a conventional electric motor in that there are electrical windings and magnets, but instead of a cylindrical geometry, it is a linear geometry with a permanent magnet on a carrier resting slightly above the electrical windings and supported by wheels or some other low friction support. As current is driven into the windings and interacts with a permanent magnet, the electromagnetic field creates thrust, which propels the vehicle either forward or backward depending on the direction of the current. A unique feature of this system is that there can be many carriers and many motors, and each carrier can be individually controlled.

Modular motors and guideway segments fit together like model train tracks, at the same time making the necessary electrical connections. The system’s compact size delivers a small footprint, in some cases a 20 to 40% reduction in system footprint. The control system manages the speed and direction of each carrier individually and keeps track of its location. The carriers are the only moving parts; they operate with a low coefficient of friction and do not require lubrication, an advantage in the clean room environment.

In the new assembly automation system, MM LITE carriers are fitted with fixtures to handle the two product orientations used during assembly. The carriers have a payload capacity of 1 kg (2.2 lb) and can travel at speeds up to 2 m/s (6.5 ft/s). Since the carriers move independently, they provide flexibility to the conveying system, allowing optimal use of each process station, as well as the ability to buffer product between stations as needed. The use of a “diverge” module simplifies the removal of rejected parts from the main line.

The new flexible automation system met or exceeded the customer’s original requirements. The use of MM LITE resulted in improvements and savings including:

- Twenty fewer redundant tools, for a capital cost saving of 28%

- Only one operator required

- Floor space reduced by 50%

- Validation cost reduced by 46%

- Flexible process for assembling three different products on the same line

“Using MagneMotion’s MM LITE system gives us a unique advantage,” said Michael Becker, President at Systematix. “The ability to move both asynchronously and synchronously enables one-up, two-up, or three-up processing. We can balance the line without redundant stations and save significant overall project costs.”

MagneMotion

www.magnemotion.com