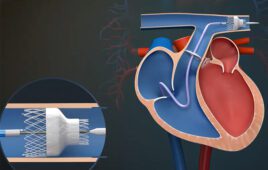

Less than two years ago, the FDA decided that perfluorooctanoic acid (PFOA) was a carcinogen and must be removed from the widely used polytetrafluoroethylene (PTFE) coatings. The coating provides a slippery surface for stainless-steel wires used to place stents, balloons and other devices in vascular treatments. PFOA is one of the surfactants historically used in processing of PTFE.

A few replacement solutions were offered. However, flakes of aqueous green PTFE were soon discovered in saline tanks in operating rooms during procedures using PTFE guidewires. FDA reports at least one instance of the coating flakes resulting in a nonfatal injury. This triggered the first recall alarm. Later reports of green flakes in sterilized packages of guidewires caused more concern and a recall was on.

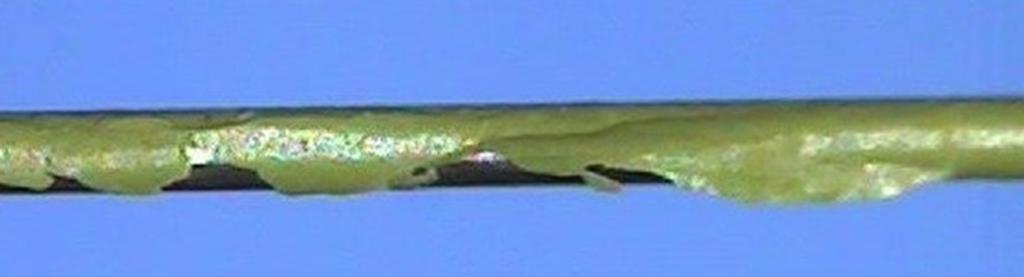

What appears to be a smooth, bonded no-PFOA PTFE coating starts to delaminate from this 304 stainless steel panel once immersed in saline for 30 minutes at 80ºF. Stainless steel 304v is used most often and had the most issues, but 316 and M2 stainless steels are also used. Source: SSG

“It turns out that the PFOA-free coatings are sensitive to saline, which degrades the hydrophobicity of PTFE, making them vulnerable to electro-chemical attack,” said Mike Osterhout, Technical Consultant at Surface Solutions Group (SSG). When immersed in even mild saline solutions – similar to those found in surgeries or body fluids – the coatings tend to blister, wrinkle, and peel off.

Looking for clues, a researcher at SSG turned an electron microscope on an uncoated stainless-steel wire and noticed residual iron ions and iron oxide. If these could be removed, a PFOA-free coating might stick better. The company devised a method for cleaning surgical wires and tested the new process. It worked. “FluoroBond-PT solves the delamination problems,” says Osterhout.

We looked at different cleaning and passivation methods, and discovered a two-part cleaner that hyper-cleans stainless steel, so the acid in the material can bite into the stainless steel where it could not do so before, adds Osterhout.

The company points out that the process is not a new coating but rather a comprehensive process that ensures adhesion. In fact, says the company, FluoroBond-PT provides adhesion of the new PFOA-free PTFE coatings equal to the “old” PTFE coatings containing PFOA.

Loss of PFOA-free PTFE adhesion is evident on a stainless steel (304v and 0.012-in. diameter) guidewire after being soaked in a 0.9% saline solution at 80°F for 30 minutes. Source: SSG

The company adds that the process is a unique and environmentally friendly treatment for stainless steel, nitinol, and other metals that solves the PTFE coating delamination issues. The process removes free iron and iron oxides from the surface, without removing material or changing the dimension of the substrate’s surface. “There has been no delamination in the field on guide wires that were coated with the process,” said Osterhout.

He adds that FluoroBond-PT is a proprietary, multi-step process that involves:

- Hyper cleaning the wire surface,

- Application of a closely controlled aqueous formulation of PFOA-free PTFE coating to the wire, then

- Aggressive testing (saline soak and rigorous tape testing) to ensure adhesion.

Post-cure testing ensures a proper coating. First, samples of coated wire are immersed in a 0.9% saline solution and held consistently at 80°F for 30 min. These are the upper limits of surgical saline and so are considered a worst-case scenario for the coating.

Once out of the saline, the samples are rinsed, dried and subjected to a tape-pull adhesion test that is beyond conventional practices. Normal ISO 2409 or ASTM 3349-02 test tapes have an adhesive strength of 0.22875 lbf/in. SSG uses tapes with three times the adhesive strength. Both tapes have excellent adhesion to PTFE surfaces.