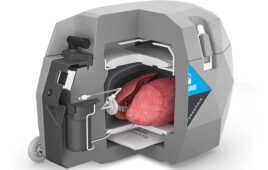

(Image courtesy of Smithwise)

A medical device development expert’s advice on charting the path to the medtech market

Eric Sugalski, Smithwise

“I need a prototype.” This is often the kick-off to my conversation with a prospective client. Usually, the idea is voiced by a clinical innovator, the CEO of a medical device startup, or perhaps an academic researcher who’s come upon a new technology or technique they’re eager to apply.

This focus on prototyping is understandable — inventors have an idea, often one they’ve been mulling over for years, and they’re eager to get it out of a sketchbook and have something tangible to prove that their technology really works. But while prototyping is a critical element of the product development process, it isn’t the same thing as the process itself. Instead, a prototype should be viewed as a byproduct, a sign and a test of the hard work that’s gone into charting and maintaining a course in the right direction.

Instead of fixating on building a slick prototype, medtech innovators should focus on proving the value their device will bring to the market and mitigating the risks that could stall or stop their progress.

Proving value to the market

Focus on value means aiming for a real impact on the way healthcare is delivered. It’s not enough to have a new way of solving a problem that’s already been solved, even if it’s a little bit better than the status quo. Demonstrable value can mean a significant change in patient outcomes and quality of life. It can also mean showing hospitals and payers a big enough cost savings over the current way of doing things to justify the pain of change.

Will your device speed recovery times, reduce hospital readmissions or time in the ICU, or eliminate the need for opiate prescriptions? You’ll need to make a compelling case that your product addresses a known problem in healthcare. That’s a challenging task. To accomplish it, you need data — a lot of it.

Data-generation is accomplished through clinical trials. Value to investors and potential payers increases exponentially after a demonstration of clinical efficacy. Until you have data to show your product can deliver outcomes that move the needle on a critical metric, your product is one idea in a sea of others just like it.

So think about the value you need to prove in order to reach your next milestone. That might be assembling a grant application or putting together a compelling, data-driven investor pitch. It will probably include prototypes, but these will likely be early-stage “Frankensteins” that don’t look much like a market-ready product.

Mitigating risks to commercialization

We often think of risks when it comes to medical technology very narrowly, as in “what is the risk to patient safety if this device fails?” Certainly, that’s one set of risks, one that has to be carefully monitored and managed throughout the development process. But there are all sorts of other risks that can keep your product from reaching the market. Risk areas include technology, clinical, legal, regulatory, payment and market.

You’ll need to do your research and construct a strategy to identify and address each of these. If a potential investor asks you about market size, regulatory pathway, reimbursement codes or prior art, you need to have a good answer that instills confidence. They won’t care if you have a great-looking prototype but no strategy to address an existing patent blocking your way.

Charting the path to market

Most medtech innovators are very aware that their resources to reach a state of revenue generation are limited. But many of them are spending those resources on the wrong things, or on the right things at the wrong time.

Medical product development is about charting your path forward in a way that spends resources efficiently to achieve key milestones along the way. Remember: Prove value, mitigate risk. There are a lot of slick prototypes packed away in closets of bright innovators who never made it to market.

Eric Sugalski is president and founder of Smithwise, a medical device development company with offices in the Philadelphia and Boston areas. He holds a B.S. in Mechanical Engineering from the University of Colorado, Boulder and an M.B.A. from the Massachusetts Institute of Technology. He is also a frequent lecturer at MIT Sloan and mentors students from MIT, the University of Pennsylvania, Drexel University and Temple University.

The opinions expressed in this blog post are the author’s only and do not necessarily reflect those of Medical Design and Outsourcing or its employees.