The complete whitepaper can be downloaded here.

The complete whitepaper can be downloaded here.

Integrating frangible seal reagent blisters into various technology platforms holds promise for more precise and reproducible results, compared to current methods in Point-Of-Care In Vitro Diagnostic testing.

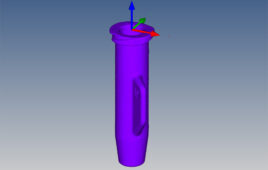

J-Pac Medical is a manufacturer of custom blisters for the medical diagnostics industry. The company creates the blisters according to application requirements, which means each sealed blister is designed with different seal strengths. The strengths can cause the blisters to be permanent or break, distort, yield on contact actuation or fail at a defined applied force, and deliver a specific amount of fluid to a target.

There are varied types of materials used to fabricate reagent blisters. They can generally be described as specialized foils and laminates used for cold- and thermo-formed packaging. The materials vary in thickness and can be applied to burst push-through, pierced, peelable and hybrid peel-push barriers.

Download the Frangible Seal Reagent Blisters Deliver Precision Performance to Point-of-Care Diagnostic Testing whitepaper here.

A meter tear-test showed that the materials used in the blisters allows the fabricator to “dial-in” the specific seal strength needed to activate but at a specific threshold. Because of this control, the medical manufacturer can be confident that the reservoirs will release their contents under a defined condition. A manufacturer can also create additional seal strengths through different material sets and processing conditions.

J-Pac’s Safe Seal blisters use precise unit-of-measure dispensing of liquids and other reagents and are easily integrated with POC platforms, such as lateral flow, microfluidic Lab-on-Chip/Card formats. This integration improves the delivery precision to the target, and by removing the conventional use of dropper bottles, eliminates sampling errors.

The company’s innovation services group designed a deal blister that would deliver 75 µl of distilled water. In order for this to happen, the blisters were fabricated, filled with a precision pipette, sealed and individually weighed. The blisters then released their contents and were weighed again to measure the amount of liquid dispensed. This was compared to a standard eyedropper that delivered 90 µl of distilled water. When compared, the eyedropper was less precise than the blister seals.

Safe Seals are fabricated with medical grade foil laminate materials that have low transmission rates. This gives the blisters a longer shelf life. A study where the blisters were filled with distilled water, placed on a scale and stored in a Yamoto DP43 oven at 60° C and 64% RH showed that less than 1% of the fluid was lost over the testing period, and can be kept on the shelf for more than two years.

All of these features can lower package and manufacturing costs, increase reagent stability, provide a smaller disposable footprint and easy, accurate fluid transfers.

Download the full whitepaper here.