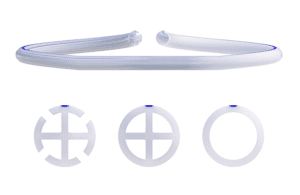

Guill Tool (West Warwick, R.I.) has launched its new reciprocating head assembly that is designed to replace the traditional tip and die assembly.

Guill Tool (West Warwick, R.I.) has launched its new reciprocating head assembly that is designed to replace the traditional tip and die assembly.

The linear reciprocating assembly changes the tube’s profile within a given length and the process is repeated throughout a single extrusion run without any interruptions. Cutting capability and extrusion speeds helps cut finished products to length.

When using the reciprocating head, only one extrusion run is needed to make a finished product. The reciprocating head eliminator the need for an assembly operation, as well as an in-process inventory. It also eliminates the need for a connecting piece and allows for JIT production and made-to-order products. Guill Tool’s new reciprocating head reduces total run time from receiving the order to shipping.