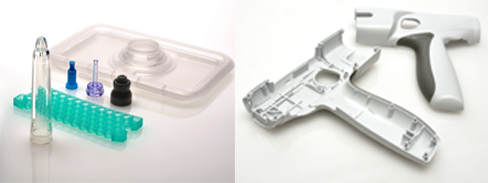

GW Plastics is a contract manufacturer that specializes in providing complex injection molded thermoplastic and silicone solutions to the healthcare, automotive and consumer/industrial industries. It uses close-tolerance mold building, molding and contract manufacturing with a matrix of competencies to meet customer needs.

Featured services:

Global Contract Manufacturing and Multi-Shot Molding Growth – GW Plastics has increased its global contract manufacturing and multi-shot molding capabilities. This summer, the company purchased several automated multi-shot machines to support newly-awarded business. GW Plastics currently operates a significant number of multi-shot presses and assembly cells across its operations, but these new machines will be the first to have an assembly cell integrated directly into the press, allowing parts to be picked and placed by robots right into assembly and secondary operations. Contract manufacturing capabilities now include highly-automated contract assembly and packaging, including form, fill, and seal and pouching.

Global Contract Manufacturing and Multi-Shot Molding Growth – GW Plastics has increased its global contract manufacturing and multi-shot molding capabilities. This summer, the company purchased several automated multi-shot machines to support newly-awarded business. GW Plastics currently operates a significant number of multi-shot presses and assembly cells across its operations, but these new machines will be the first to have an assembly cell integrated directly into the press, allowing parts to be picked and placed by robots right into assembly and secondary operations. Contract manufacturing capabilities now include highly-automated contract assembly and packaging, including form, fill, and seal and pouching.- Doubling Liquid Silicone Rubber Clean Room Molding Space – Over the past year, GW Plastics has doubled the size of its clean room molding space for its affiliate, GW Silicones, in response to an increase in overmolding projects with silicones on thermoplastics. This added space is a continuation of a 2015 expansion to enlarge the entire Royalton campus, which is located near its corporate headquarters in Bethel, Vt. and also houses its mold-building and validation center, a brand-new Process Development and Training Center, thermoplastic molding operations, and warehousing space. In addition to added machinery and technology, GW Silicones can now provide services from design to mold-building to high-volume manufacturing.

Visit GW Plastics at DeviceTalks Boston.

[Hear from some of the best minds in medtech at DeviceTalks Boston on Oct. 2.]