Developing innovative catheters and minimally invasive surgical devices is hard. These strategies spur inventive solutions and unlock the path to success.

Don Baumgarten, Product Creation Studio

Minimally invasive knee surgery (iStock photo courtesy of Product Creation Studio)

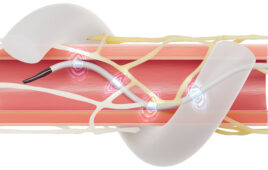

Minimally invasive surgery (MIS) offers compelling benefits compared to traditional open surgery, such as faster patient recovery, reduced risk of infection and lower healthcare costs. To improve MIS capabilities, medical device companies are continually working to advance catheter and device technologies and bring new products to market.

Developing those innovative products is a formidable task. By their very nature, MIS devices have small working elements, which greatly complicates development. The miniaturization of mechanisms, electrical modules and diverse technologies is technically difficult work. Engineering teams can quickly find themselves facing seemingly impossible challenges. Here are a few strategies to make inventive breakthroughs possible in these difficult development efforts:

Generate a wide variety of solution options

An engineering team can encounter numerous technical challenges when developing new features and functional capabilities for MIS devices. A common pitfall is to quickly focus on the first clever idea proposed to solve a new problem. Rarely will the first good idea turn out to be the fastest to develop and have the best performance and lowest manufacturing cost. Worse, the development team can hit a dead end if the concept ultimately turns out not to meet functional requirements or if the manufacturing cost is too high.

It’s better to generate a wide variety of solution concepts for significant technical challenges because the expected development time, level of performance and manufacturing cost can vary greatly among concepts. The team will also have options if a favored idea doesn’t pan out, and might actually discover a concept with the potential to function better than others for a lower manufactured cost.

How can a team generate such an ingenious idea? Effective ideation sessions stimulate team creativity and often produce inventive ideas not previously considered. Use ideation sessions when substantial technical problems arise. The time needed to conduct an ideation session is minor compared to overall development time, and focused ideation is often the key to generating creative, breakthrough ideas.

Investigate multiple concepts

After creating and assessing a variety of concepts, it can be tempting to commit to a favorite idea before it’s actually been proven to work. Selecting a single concept too early adds substantial risk to the development effort because technical designs don’t always function as expected. Even promising concepts can ultimately fail.

The unusual physical characteristics of MIS devices and unique surgical applications make the performance level of technical concepts hard to predict. A concept can perform much better or worse than expected. The more novel the concept, the less predictable the outcome.

With that in mind, it’s best to investigate several leading concepts to give the team options if a preferred concept is not viable. Building and testing proof-of-concept prototypes for the best ideas enables the team to make informed comparisons of functional performance, development risk and manufacturing cost before choosing a single concept.

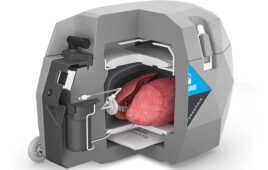

Use large-scale prototypes

The unique development challenges presented by catheters and MIS devices often necessitate a relatively high number of prototype design-build-test cycles to achieve the desired functionality. Building prototypes at actual size (1:1 scale) can be time-consuming and expensive because the unique components, such as catheter sheaths and minuscule parts, must be ordered from highly specialized suppliers. The cost and schedule needed for design iterations can become untenable.

It often works well to conduct initial design iterations using large-scale prototypes. Iterations can be much faster and less expensive at 2:1, 5:1, or 10:1 scale because components can generally be fabricated using standard machining and manufacturing processes, 3D printing, and by modifying off-the-shelf components. The goal is to solve as many functional issues as possible at the larger scale to minimize the number of design iterations needed at actual size.

Catheter sheaths and other highly specific components can be approximated at larger scale, although some properties of those components cannot be readily duplicated. Even with those limitations, the quick learning made possible by large-scale prototypes is extremely valuable.

Be strategic to be innovative

Teams must overcome numerous technical challenges to bring new catheters and minimally invasive devices to market. Using deliberate strategies to tackle these difficult development efforts can enable your team to make the breakthroughs needed for project success.

Don Baumgarten is director of mechanical engineering for Product Creation Studio. He has participated in the design and manufacture of medical devices for startups to Fortune 500 companies, including Philips, Boston Scientific, GoPro, Pathway Technologies and Intellectual Ventures.

The opinions expressed in this blog post are the authors’ only and do not necessarily reflect those of Medical Design and Outsourcing or its employees.