Laser processing provides automation and efficiencies that help meet FDA regulations and produce superior medical device components.

David Locke, ACSYS Lasertechnik US

Laser-marked hearing aid (Image courtesy of ACSYS Lasertechnik US)

Laser systems have become essential to the production of better-designed medical devices. The precision, repeatability, and scale needed to manufacture next-generation medical products rely heavily on lasers’ advantages to contract manufacturers and medtech manufacturing. MarketsandMarkets Research expects the laser technology market size to grow from $11.7 billion in 2020 to $17.6 billion by 2025 due to the growing demand from healthcare coupled with the performance lasers achieve compared with legacy material-processing procedures.

So let’s review how laser cutting, engraving, welding and marking enhance medical device designs. We’ll look at the various applications and the qualifications all medical device manufacturers should be familiar with before planning and building a complex laser system as part of the product manufacturing process.

Application types

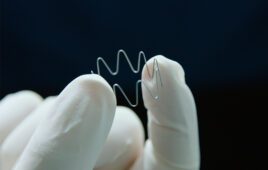

There are numerous applications for lasers in medical device and surgical instrument manufacturing. For example, endoscopes, surgical knives and probing devices, wire stents, vascular clamps and stent markers all require welding, engraving and cutting operations for manufacturing.

Compact implantable devices, such as pacemakers, can benefit from improved manufacturing using laser processes such as precision engraving, welding and cutting. In the case of laser welding, there is a significant reduction in heat output from this process compared to conventional welding.

Laser welding delivers a very small heat-affected zone, which typically leads to less need for follow-up processes such as trimming and grinding than devices welded through traditional methods. It also means tighter welds to produce smaller micro-pieces and allowing welds to occur in smaller physical footprints. A smaller heat-affected zone also enables rapid cooling. Curtailing the amount of heat annealing that occurs over the surface contour of a piece delivers fewer chances of deformation and less scrap.

With some medical devices, it’s important to limit physical contact with the parts due to sterility concerns. Think smaller implantable devices and devices that contain microelectronic systems with electrodes (such as pacemakers, auditory implants and pumps), which often require hermetical sealing. The devices benefit from through-transmission lasering, where parts are clamped together and treated with a pinpoint laser beam in precision laser welding. Pulsed laser welding is another process used for implantable devices, as it works well for sealing the titanium cans utilized in these devices.

Laser-welded joints in a medical device can withstand high-temperature sterilization, possess pore-free surfaces and typically eliminate the need for secondary finishing operations processes, which is a crucial requirement for biocompatible components.

Medical instruments — including endoscopic instruments, bone screws, surgical devices & blades, bellows, and diaphragms — almost always require some kind of permanent marking such as a serial number or UDI (unique device identification) to provide patient protection. There are also notable laser drilling applications on microfluidic sensors and sensor disposables. Laser marking and engraving performs these requirements elegantly in the form of a marker band, bar code or 2D data matrix code.

Process validation and qualification of laser system solutions

Process validation serves as a form of documented verification to show that it’s possible to manufacture a product in a defined process sequence, with all manufacturing qualification requirements addressed. The qualification of laser processing systems for the manufacture of medical products is a clearly defined requirement from the rules of Good Manufacturing Practice (GMP). The laser systems provider and medical device manufacturer often collaborate during process validation to ensure that functional requirements of the component are met reliably and consistently.

Several regulations govern process validation, especially covered under the standards for ISO 9001, ISO 13485, and 21 CFR Part 820. While validation can be a complicated and laborious process, it can also produce some meaningful benefits. The data derived from validation can help troubleshoot issues and reduce validation efforts during inspection, saving time in the manufacturing process.

Validation also assures complicated processes remain consistent and reliable and mitigates risk to the device maker and the patient. Technical expertise and deep experience in laser systems must encompass quality engineering know-how and a comprehensive understanding of the laser process itself.

Lasers’ impact on the future

Laser technology is transforming medical device manufacturing these days. As a result, contract manufacturers and medical device OEMs benefit from more efficiency, accuracy, reliability and scalablility at much lower costs than before — all while achieving higher-quality medical devices and instruments for healthcare providers to use.

Precision laser systems excel in the creation of corrosion-resistant black marks and surface texturing with new ultra-short pulsed (USP) lasers, while permanent UDI and other marking with short-pulsed lasers of various wavelengths continue to expand. There are advancements in cutting and welding thin materials with pulsed, continuous-wave fiber and USP lasers, resulting in high-quality edges and minimal thermal distortion.

Many medical device parts are now made via 3D printing from metal powders, creating the ability for mass-customization with the possibility of using other laser systems to selectively polish surfaces to very high smoothness. Automation advancements through robotic loading and vision systems to locate, orient and confirm parts and processes mean longer-term lights-out production is possible. The ability of systems builders to apply and integrate laser technologies enables advancements in technology that translate into increased capabilities and throughput for medical device manufacturers.

David Locke is technical sales manager for ASCYS Lasertechnik US, where he advises customers on customizable laser systems for cutting, marking, welding, and engraving. He has a degree in physics from St. Michael’s College and has worked in the industrial laser industry since 1984.

The opinions expressed in this blog post are the author’s only and do not necessarily reflect those of Medical Design and Outsourcing or its employees.

This article originally ran on April 19, 2021. Updated with edits.