K2M Group said today it won FDA 510(k) clearance for its Capri small 3D static corpectomy cage system, touting it as the 1st-to-market 3D-printed, FDA-cleared device of its kind.

The newly cleared device is designed for stabilizing the thoracolumbar spine during vertebral body resections as a result of trauma or tumors, the Leesburg, Va.-based company said.

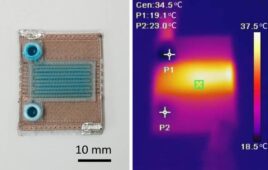

The device has a porous structure and rough surface architecture to allow for bony integration through it, and features lordotic options to help support the anterior spinal column to help achieve sagittal balance.

“Capri Small 3D Static provides me with a corpectomy cage that incorporates the Lamellar 3D Titanium Technology to treat patients with complex pathologies. The incorporation of pores into the endplates increases the surface area for fusion and presents the potential for bone to grow into the corpectomy cage,” Dr. Michael Finn of the University of Colorado said in a prepared statement.

K2M said that the device uses its Lamellar 3D titanium technoogy which creates structures “impossible with traditional manufacturing techniques” which in pre-clincal trials have been shown to be associated with bone growth activity.

“K2M’s excellence in 3D-printing innovations allows us to aid surgeons in treating spinal pathologies across MIS, degenerative, and now complex spine segmentsToday, we are excited to introduce CAPRI Small 3D Static, a 3D-printed surgical solution for correcting complications from trauma or tumor in complex spine cases. This is our third product family—which already includes the Cascadia 3D family of static interbodies and the Mojave PL 3D Expandable Interbody—to feature Lamellar 3D Titanium Technology. K2M is leading the way in 3D spinal solutions—as evidenced by our comprehensive Balance ACS platform and our market-leading 3D-printed portfolio—and our disruptive technologies provide surgeons with both diagnostic and therapeutic solutions to treat patients around the world,” prez & CEO Eric Major said in a press release.

[Want to stay more on top of MDO content? Subscribe to our weekly e-newsletter.]