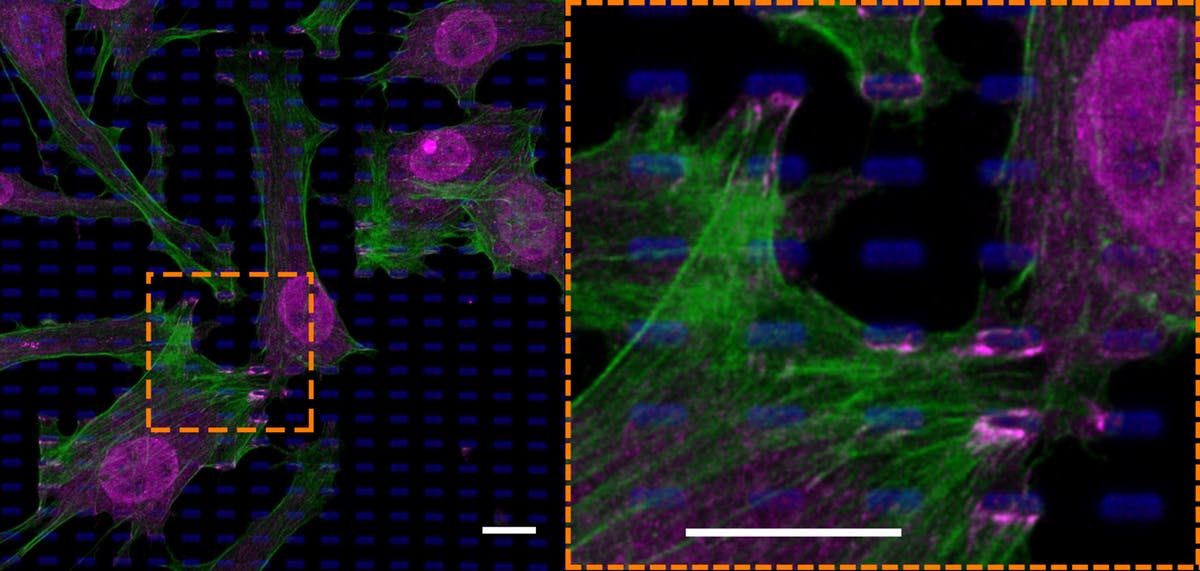

This immune fluorescence image shows murine mesenchymal stem cells grown on top of the hybrid material with their cytoskeleton stained in green and nuclei and cell contact sites stained in magenta. In the magnified segment, contact sites can be seen as doted structures at the tips of the microplates (blue) that emanate from the material’s surface. (Credit: Wyss Institute at Harvard University)

Cells in developing tissues respond to local mechanical forces by adjusting their growth, differentiation and migration patterns. Being able to mimic these changes accurately outside the body could lead to a better understanding of the underlying molecular mechanisms and create new opportunities for tissue engineering and drug development.

Current available cell manipulation methods, however, either investigate the behavior of single cells taken out of their natural tissue context, or they deform entire cell sheets without control over individual cells.

A study reported in Nature Communications now presents a new approach that bridges this gap in cell manipulation. The team from the Wyss Institute for Biologically Inspired Engineering at Harvard University, the Harvard A. Paulson School of Engineering and Applied Sciences (SEAS) and the Department of Chemistry and Chemical Biology at Harvard’s Faculty of Arts and Sciences (FAS) has developed a hybrid material that can enable highly controllable cell deformations on dimensions ranging from an entire cell sheet down to small areas of individual cells.

“With its unique abilities, relative ease of synthesis and use, our new materials approach overcomes existing experimental limitations, and could advance the investigation of force-related aspects of cell morphogenesis, cell movements and cell-cell interactions in a highly controllable and more life-like in vitro format,” says Joanna Aizenberg, who is a Wyss Institute Core Faculty member, Professor of Chemistry and Chemical Biology and the Amy Smith Berylson Professor of Materials Science at SEAS.

The method embodies versatility regarding the scales at which it can be performed — it can be applied to single cells or microorganisms and also to larger networks of cells like those that form actual tissues. Moreover, it enables new investigational tools for different research areas, including cell and developmental biology, regenerative medicine, and even drug testing.

This broad spectrum of possible applications is rooted in the material’s design and activation. The research team’s idea is that of an architecture consisting of a “skeleton” component made of arrays of tiny microplates embedded in a hydrogel, the “muscle” component.

Cells that are grown on the top surface of this hybrid material tightly adhere to the tips of neighboring microplates. The hydrogel can be locally heated up and induced to contract like a muscle, by shining a focal laser light on it, pulling closeby microplates apart and stretching cells on the surface. This process is safe for cells as they are not heated together with the hydrogel and it is quickly reversible.

This cartoon explains how a focal laser light pointed at an area of the photo-responsive hydrogel causes it to locally contract, passively pulling at the embedded microplate tips and the cell structures attached to them. As shown in the top view of the hydrogel pictured in the clip, the displacement of the microplate tips in local areas happens fast and is entirely reversible. (Credit: Wyss Institute at Harvard University)

“By varying the patterns and dimensions of the microstructure skeleton in the hydrogel, we are able to generate optimal substrates for different cell sources, and by varying the positioning and distribution of the laser light, we can manipulate either single cells and subcellular areas within a complex cell sheet, or larger segments of the sheet,” says Tanya Shirman, a Technology Development Fellow at the Wyss Institute, who is a co- author of the paper leading the materials development effort in this project. “The applied forces and response times mirror those in real tissues and are thus highly physiological.”

The versatility of this newly developed dynamic material platform may also allow many applications that are not related to cell studies or tissue engineering, including those in the fields of stimuli-responsive materials, actuators, robotics, active antifouling surfaces, and adaptive optics. For example the movements of robots and deformation of synthetic joints could be controlled with light directed at critical areas, or industrial surfaces could be cleared from contaminating organisms by shining the light at the fouled region inducing local actuation of the surface and releasing the contaminants.

“This new dynamic mechanoresponsive material technology offers an exciting new non-invasive way to perturb the cellular microenvironment that could lead to new understanding to how cells sense and response to different frequencies or patterns of mechanical activation, which is difficult with conventional mechanobiological methods. It also could result in engineering entirely new types of robotic control interfaces,” says Wyss Institute Founding Director Donald Ingber, M.D., Ph.D., who also is the Judah Folkman Professor of Vascular Biology at Boston Children’s Hospital and Harvard Medical School, and Professor of Bioengineering at SEAS.

The article is also authored by a Graduate Student from Harvard University’s Department of Chemistry and Chemical Biology (CCB), researchers Lauren Zazar and Amy Sutton, who is the study’s first author and a graduate Student with Aizenberg and. Additional authors are SEAS researchers Jaakko Timonen, Grant England, and Philseok Kim, who is also a Visiting Scholar at the Wyss Institute, Elizabeth Strong from Harvard College, Wyss Institute’s Thomas Ferrante as well as MIT researcher Mathias Kolle and PennState researcher Lauren Zarzar, a former CCB Graduate Student.