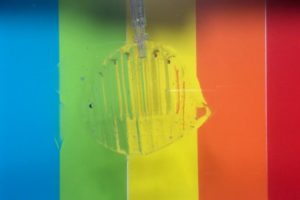

“Hydrogels are soft, wet, biocompatible, and can form more friendly interfaces with human organs,” says Xuanhe Zhao, associate professor of mechanical engineering and civil and environmental engineering at MIT. [Photo courtesy of Hyunwoo Yuk/MIT Soft Active Materials Lab]

Tough, rubbery and mostly water, these robots can perform an array of tasks including kicking a ball or grabbing and releasing live fish.

The transparent robots move by having water pump in and out of them and consist of an assortment of hollow, hydrogel structures that are connected to rubber tubes. When the robots fill with water, the hydrogel structures inflate and the robot can bend and stretch.

Xuanhe Zhao, associate professor of mechanical engineering and civil and environmental engineering at MIT, led the group to create this robot with hopes of incorporating it into medical applications in the future.

“Hydrogels are soft, wet, biocompatible and can form more friendly interfaces with human organs,” said Zhao in an MIT news release. “We are actively collaborating with medical groups to translate this system into soft manipulators such as hydrogel ‘hands,’ which could potentially apply more gentle manipulations to tissues and organs in surgical operations.”

Since the hydrogels are comprised of mostly water, Zhao said they are safer for use in a biomedical setting. Other soft robots are made from rubbers and silicones that do not have the biocompatibility that hydrogels have.

The Harvard Biodesign Lab is also doing research on soft robotics that are made with embedded flexible materials and are built to assist people who have lost motor control because of a stroke.

Zhao and his group of engineers have spent the past five years trying to develop a combination of polymers and water that worked as hydrogels. They wanted a material that was tough but could be highly stretchable. The team realized that the hydrogels could be manipulated enough to be used as a soft robot because of its durability and flexibility.

Taking the idea of the way glass eels maneuver in the sea, the engineers developed the hydrogel soft robot using 3D printing and laser cutting techniques. This allowed Zhao and his colleague, graduate student Hyunwoo Yuk, to be able to print the hydrogel recipe into robotic structures and bond those structures to small, rubber tubes that are connected to pumps.

This is not the first time scientists have drawn inspiration from aquatic life when designing robots with potential medical applications. Harvard scientists created a synthetic stingray in 2016 that was propelled using living muscle cells and was controlled using light. They hoped that using the same technique used to make the synthetic stingray could be used to build an artificial heart.

When it comes to the MIT robot, a syringe pump injects water through the hollow structures to move the robot, making the robot curl and stretch. Zhao and Yuk realized that they could make fast and forceful reactions by pumping water into the structure and create a few neutrons of force in the matter of one second. In comparison, other hydrogel robots have let water drip into the structures naturally which created millinewton forces within several minutes or hours.

Next, the engineers created a hand-like structure for the hydrogels, after realizing that they were able to go through up to 1,000 cycles without rupturing or tearing. Pumping water in and out of the structure made the finger-like structures open and close fast enough to grab a goldfish that was swimming by.

The research was supported by the Office of Naval Research, the MIT Institute of Soldier Nanotechnologies and the National Science Foundation and was published online in the Nature Communications journal.

[Want to stay more on top of MDO content? Subscribe to our weekly e-newsletter.]