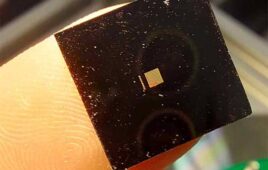

[Photo courtesy MIT]

The design approach relies on thermodynamic interactions that drive molecular building blocks to take on different configurations, known as self-assembly.

“The more antibodies you put on a surface, the lower the concentration of molecules you can detect,” said associate professor of chemical engineering and senior author of the study Bradley Olsen. “You can have a big impact on biosensors by potentially improving the sensitivity by several orders of magnitude.”

Antibodies and other proteins can form layers by attaching polymer tails to proteins. The molecules then arrange themselves into a structure that makes sure the proteins and polymers do not interact since they repel from each other.

Olsen and his research team connected the proteins to the polymer chain PNIPAM. A thin film, containing anywhere from 10 to 100 layers of the protein-polymer structure, formed when they coated the molecules onto a surface. Layering antibodies on top of other antibodies in these layers makes sensors more sensitive.

“Because the protein and polymer are bonded together, they can’t separate like oil and water. They can only get apart from each other by a distance about the size of one molecule,” Olsen said. “If you do this in three dimensions, then you get things like cylinders of protein surrounded by polymer, or alternating layers of protein and polymer.”

The researchers made 3D arrays of human immunoglobulin (IgG) antibodies using self-assembly and made the antibody sensors 100 times more sensitive. The arrays also had nanoscale channels that let samples flow throughout the entire sensor.

Olsen is using this Air Force Office of Scientific Research and Arnold and Mabel Beckman Foundation-funded research to create sensors with antibodies to identify pathogens in blood or urine samples, which could also identify biomarkers in sweat or saliva and monitor health.

The study was led by MIT postdoc Xue-Hui Dong with former postdoc Allie Obermeyer and was published online in the Angewandte Chemie journal.

[Want to stay more on top of MDO content? Subscribe to our weekly e-newsletter.]