The days of siloed manufacturing in the medical device industry are all but gone. No longer can OEMs find a contract manufacturer that just does one thing. A case in point is the medical molding industry – almost all molding companies have moved beyond the “we just make parts” mentality. Most offer design assistance, and other pre-work, plus after-mold services up to and including packaging and sterilization.

More than one molder tells Medical Design & Outsourcing that the drive to offer expanded services is always based on meeting customer needs and trying to stay ahead of the bigger contract companies. Many have built strong reputations based on years of experience in the medical technology market. These experts have responded to customer needs in multiple ways.

IP protection

MRPC is an ISO 9001 and ISO 13485 custom manufacturer of silicone, medical rubber, and thermoplastic components and assemblies. The company specializes in two-material molding, micromolding, silicone molding, and long-term implantable molding.

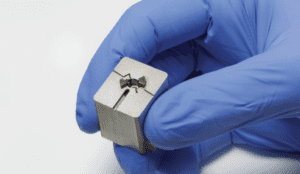

Ultra-precision tooling inserts created at MTD. Successful micromolding begins with exact tooling execution.

“We do it all in our facility. We want to be thought of as high-quality build for molds and molded parts, and a short-run production source,” says Mark Brandstaetter, VP of sales and marketing, noting that MRPC is privately held.

“There is a lot of uncertainty in IP protection and ownership, but with privately held companies, that uncertainty is diminished,” he says.

MRPC has recently expanded its services to include pouch packaging. “We are doing more of those downstream activities,” to better serve clients, Brandstaetter explains.

Above all, Brandstaetter says his company puts an emphasis on quick turnaround. “Fast manufacturing is very important to industry. We can bridge the gap from prototype to production.”

Micromolding to the rescue

MTD Micro Molding is a specialty house in the truest sense, says Director of Marketing Lindsay Mann. The company is solely focused on the micromolding of advanced medical products.

“We serve clients best that have projects that possess a level of ‘impossible,’” says Mann. Her challenge is different from other molders because of the specialized requirements of micromolding technology, she explains. “Micromolding requires a significant level of know-how,” she says. “We need to have a thorough, up-front view of the project to make sure we are putting our potential clients on the right path.”

If a client’s design doesn’t meet the criteria that MTD’s specialized process requires, Mann says, “it’s better to be honest about it.” MTD takes its role as an educator seriously. And it also sees itself as a problem solver. “Because we are a specialty house, 25 percent of our business is rescue projects from companies that failed with another molder,” she notes.

No surprises

Sil-Pro is a contract manufacturer specializing in the design & development, manufacturing, assembly, and packaging of silicone and thermoplastic devices, components, and machined parts. Marketing Coordinator Rebecca Talbot says the firm’s sweet spot is that it offers total manufacturing & assembly and post-assembly services from a single location, what Talbot calls “downstream processes and uses.”

Contract manufactured custom vascular introducer assembly. The part comprises molded silicone, molded thermoplastic and was assembled and sonic welded by Sil Pro.

Sil-Pro’s best clients come in with a design and work closely with the firm to flesh it out, Talbot says. “The one thing no one wants is surprise,” she says, remembering a client with a complex molding design. The group agreed on a material and process, but the client wasn’t able to convey that the final part needed to withstand a certain temperature. Such detail is important and can influence the material selection and the geometry of the part. “We can do complicated geometries and cavitations, but we need realistic expectations,” says Talbot.

The best way to avoid such a scenario is to have an open, communicative relationship, she says. Collaboration comes down to ensuring you have good technical people and that both sides ask the right questions. “The more you inform the CM, the better the manufacturing and the better the product. You don’t want to waste money, so you have to be ready to collaborate.”

Location, location, exchange rate

Freudenberg Medical is a complete silicone and plastic injection-molding firm with assembly, cleanroom and R&D support. All of the processes happen under one roof in either Gloucester, Mass., or at Freudenberg’s headquarters in Carpinteria, Calif., says Don Durand, business development manager. He says keeping individual projects together improves the company’s internal process in order to improve the quality of the part.

A client approached MTD with a suture device design, seeking a product with minimal inherent viscosity loss and crisper features to improve functionality. While most competitors had difficulty realizing less than a 20% IV loss, MTD developed a superior fastener with an IV loss of less than 4%.

Moore Med Tech is a custom injection molder that develops and optimizes plastic medical products. Jerome Mercier, sales coordinator at Plastiques Moore, touts the company’s 44 years of experience in injection molding. The company has ISO 13485 certification and produces parts in an ISO 8 cleanroom. Sometimes it’s not only the quality of the services you offer, but the ability to offer something others might not. In Moore’s case, Mercier says the company’s Quebec City location is an additional incentive because of the exchange rate between the U.S. and Canadian dollars (at the time of this writing, $1 was worth nearly C$1.31).

Thinking big and early

Nypro is an example of a traditional medical molder that has moved on to bigger ideas. The company, which provides metal injection molding and silicone molding services, was acquired by Jabil in 2013. The new resources provided by the merger support Nypro’s expanding view; senior business unit director Alex Privert says the company is focusing on connected health with a “blue sky” innovation center and a pipeline for 3D scanning and ideation.

“Many of our competitors have small R&D departments, but our sweet spot is the front-end innovation,” Privert says. “You can give us your tough jobs.”