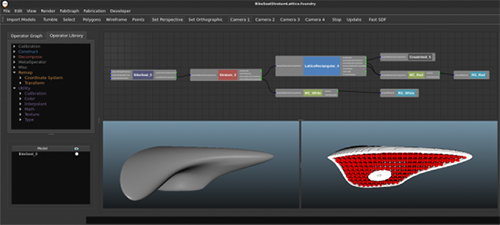

Foundry’s interface makes it easier for non-engineers to create their own designs for 3-D printed objects such as bike seats. (Credit: Kiril Vidimče/MIT CSAIL)

While 3-D printers have been involved in the development of medical products, MIT has developed a new software that makes printing multiple materials easier.

“Foundry” is the newest 3-D printing software that allows designers to custom design products with several materials all at once. In the original process, if a product was made up of multiple materials, pieces had to printed out separately and assembled later.

According to Design-Engineering, “Student Kiril Vidimče explains that the program is like Photoshop for 3D printed materials, allowing the user to design object made of new composite materials with optimal properties for any given project.”

To use this software, you have to first design your product in a traditional computer-aided-design (CAD) and export the file. Next, you can decide what the product will be made up of and choose to use more than one material. The software also allows designers to see a preview of the final product rather than waiting until the end.

Prior to the development of this new software, universities and other medical organizations have been creating medical implants such as stents, kidneys. The MIT software design team was able to create a bone that may be used for planning surgery. In the future, other products could include dentures and products that need both soft and tough material.