Dow Corning, a global leader in silicones, silicon-based technology and innovation, unveiled Dow Corning LC-3335 3D Printable Silicone Rubber here at formnext 2016. Developed in collaboration with German RepRap GmbH, the leading German manufacturer for fused filament fabrication (FFF) 3D Printers, this breakthrough new materials technology is perhaps the first Dow Corning solution to be formulated specifically for designers seeking to combine the performance benefits of silicone with the design and processing advantages of their additive manufacturing process.

Dow Corning, a global leader in silicones, silicon-based technology and innovation, unveiled Dow Corning LC-3335 3D Printable Silicone Rubber here at formnext 2016. Developed in collaboration with German RepRap GmbH, the leading German manufacturer for fused filament fabrication (FFF) 3D Printers, this breakthrough new materials technology is perhaps the first Dow Corning solution to be formulated specifically for designers seeking to combine the performance benefits of silicone with the design and processing advantages of their additive manufacturing process.

“LC-3335 3D Printable Silicone Rubber is representative of what close collaboration between a leading materials supplier and a top 3D printing equipment company can achieve,” said Hugo da Silva, global industry director for lighting and 3D printing at Dow Corning. “More than simply a technological achievement, this patent-pending breakthrough material introduces the power and versatility of silicone technology into the realm of 3D printing. Dow Corning customers can now combine the uniquely beneficial properties of our silicones with faster prototype development and small series production of highly complex parts.”

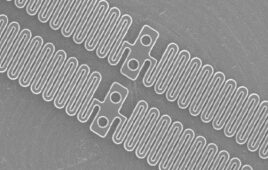

German RepRap designed its patent-pending 3D Printer to print successive layers of LC‑3335 3D Printable Silicone Rubber in a method comparable to the FFF process. Thus, it can form complex silicone parts that would be difficult or impossible to achieve through conventional injection molding. Each layer of silicone is fully cross-linked through thermal cure to enable parts with mechanical properties that are comparable to molded components.

Test parts printed with LC-3335 Silicone on German RepRap’s platform exhibited the same sharp cure profile of injection molded test samples, as well as 80 percent (on average) of the samples’ mechanical properties. Specifically, 3D printed parts demonstrated 70 percent of the tensile strength elongation of injection molded samples, and 90 percent of their tear strength. Consequently, with German RepRap’s platform, Dow Corning LC-3335 3D Printable Silicone Rubber is potentially capable of printing functional prototypes and enabling small manufacturing trials of complex parts. Further, the material’s properties closely match those of liquid silicone rubber (LSR), allowing an easy transfer into injection molding processes for high-volume manufacturing.

Dow Corning is committed to collaborating with leading equipment makers to extend the benefits of its industry-leading silicone materials and expertise to the fast-growing field of 3D printing. Additive manufacturing promises to accelerate the design-to-production process by quickly converting digital designs into functional parts for low- to medium-volume manufacturing without the time or cost required to first build a molding tool and prototype. Consequently, the technology can significantly reduce production waste, optimize the supply chain, eliminate tooling and speed the time to market for new designs unachievable through conventional technology.

LC-3555 Printable Silicone Rubber expands design options in automotive, healthcare, cookware, lighting and other applications where traditional LSRs are used. Dow Corning is currently exploring future silicone rubber products for 3D printing, including optical- and medical-quality grades, UV-curable materials and other innovative solutions.

Dow Corning

dowcorning.com

Dow

dow.com

German RepRap GmbH

germanreprap.com