NN, Inc. Precision Engineered Products Group (PEP), a global manufacturer of highly engineered precision customized solutions serving the medical market, announced it has completed the validation and production readiness qualification of its direct-metal laser sintering (DMLS) process technology.

NN, Inc. Precision Engineered Products Group (PEP), a global manufacturer of highly engineered precision customized solutions serving the medical market, announced it has completed the validation and production readiness qualification of its direct-metal laser sintering (DMLS) process technology.

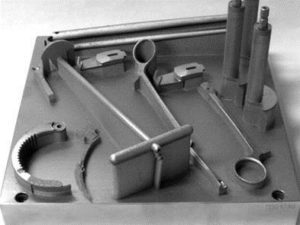

In keeping with its strategy of innovation and providing engineered solutions, NN, Inc. PEP has secured the DMLS additive manufacturing equipment and has spent the last several months in rigorous development and testing in order to qualify this advanced technology for production. The DMLS machines—EOS M280 and EOS M290—are each dedicated to their respective materials: 17-4SS and Ti 6-4 ELI. This avoids the possible compromising or mixing of materials experienced by DMLS providers who routinely use multiple types of powders in a single DMLS machine.

Once a product has been produced at NN, Inc. PEP’s Additive Manufacturing Center of Excellence, designers and developers can review outcomes together for optimal results.

Customers who specialize in orthopedic instruments and implants have been among the early adopters of this technology. As the technology continues to evolve, the company expects it will continue to extend across the medical device industry and other end markets.

Clients on a global scale recognize the quality of NN PEP’s manufacturing capabilities, resulting in a rapidly growing customer base. To meet the customer demand for its additive manufacturing services, the company has appointed Daniel Anderson as Director of Emerging Technologies to help lead the initiative. Anderson has nearly 30 years of experience in the medical device industry.

NN, Inc.

pep-corp.com