Piper Plastics, a provider of high performance polymer materials and precision machined plastic components and assemblies, has developed a proprietary high pressure molding technology that yields near net shape polymers up to 2” thick without porosity, voids or sinks.

Piper Plastics, a provider of high performance polymer materials and precision machined plastic components and assemblies, has developed a proprietary high pressure molding technology that yields near net shape polymers up to 2” thick without porosity, voids or sinks.

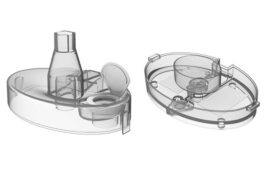

The process, which utilizes molding equipment designed and developed by Piper Plastics, allows the company to mold high performance thermoplastics, filled or unfilled, with isotropic mechanical properties. “This capability is especially beneficial for large CNC machined parts that were historically limited to extruded or compression molded stock shapes,” explained Dave Wilkinson, Materials Engineering Manager, Piper Plastics. “In comparison to extrusion and compression molding, this new process yields parts that have higher strength – typically 15-20% stronger than extruded shapes, and 50% stronger than compression molded shapes – plus more consistent mechanical properties.”

A major reason for developing the new technology was to save costs when machining finished parts from expensive high performance materials such as PEEK, PAI or TPI. “The molds are inexpensive since we are only molding a near net shape that will be machined after molding,” said Bruce White, Vice President, Piper Plastics. “Because it’s close to the final part, a near net shape requires less machining. Less machining means less waste – which is an important consideration for green and sustainable programs.”

The technology also allows Piper to offer small batch runs for mating the right polymer or blend for an application. “Distributors typically only carry about 50 types of engineering plastics but with this technology we can mold custom blanks from over 3,000 polymers and compounds, or develop a compound specifically for an application,” said White.

The process is suitable for larger parts and weights of up to 6 pounds per blank with large and varying wall thicknesses and complex geometries. “Near net shape is effective for parts that cannot be produced using standard injection molding because the cross sectional area is too thick,” said Wilkinson. “This new technology has opened up exciting opportunities in the semiconductor, oil and gas, medical equipment, and aerospace markets.”

Piper Plastics

piperplastics.com