The wirelessly connected hospital requires battery-powered medical devices designed to operate reliably at all times.

Sol Jacobs, Tadiran Batteries

Lithium thionyl chloride (LiSOCl2) batteries [Image courtesy of Tadiran Batteries]

As nurse-to-patient ratios continue to grow, the “connected hospital” provides access to accurate and timely data that frees caregivers to spend less time on administrative work so they can focus on providing the best quality of care possible to a growing patient population.

Advanced lithium batteries ensure continuous connectivity

To deliver the highest quality of patient care, battery-powered medical devices should be designed to operate reliably at all times. This demands a thoughtful choice of batteries.

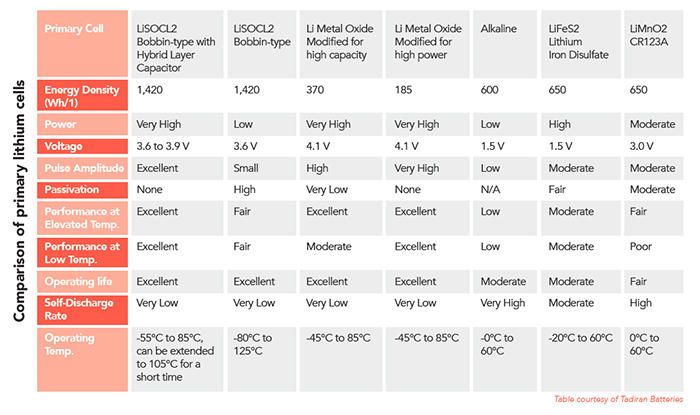

Various primary (non-rechargeable) battery chemistries are available, including alkaline, iron disulfate (LiFeS2), lithium manganese dioxide (LiMNO2), lithium thionyl chloride (LiSOCl2) and lithium metal oxide. (See table below.)

Lithium batteries power a wide variety of medical devices, including automatic external defibrillators, surgical power tools, robotic cameras, RFID asset tags, infusion pumps, bone growth stimulators, glucose monitors, blood oxygen meters and cauterizers. Lithium battery chemistry offers the highest specific energy (energy per unit weight) and energy density (energy per unit volume) of any battery type, along with nominal open circuit voltages ranging from 1.7V to 3.9V, which allows products to be miniaturized.

Bobbin-type LiSOCl2 batteries are ideal for wireless medical applications that require low average daily current and permit extended battery life of up to 40 years. Due to the absence of water and the chemical and physical stability of the electrolyte materials, bobbin-type LiSOCl2 cells can also withstand extremely high temperatures.

Bobbin-type LiSOCl2 batteries are also uniquely suited for the medical cold chain, where transplant organs, tissue samples, and pharmaceuticals must be continuously monitored during transport at -80°C.

The typical hospital setting also offers abundant opportunities for deploying consumer-grade alkaline and rechargeable lithium-ion (Li-ion) batteries, especially for non-essential medical devices that do not pose a life safety threat if the battery fails and needs replacement.

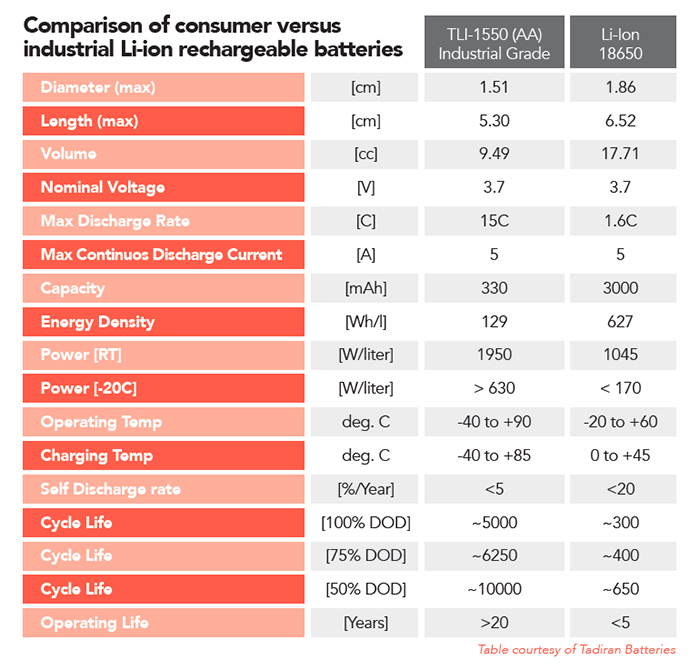

Consumer grade rechargeable Li-ion batteries have limitations such as a limited lifespan of five years and 500 full recharge cycles, a relatively narrow temperature range (-20°C to 60°C), and the inability to deliver the high pulses required for two-way wireless communications. By contrast, industrial-grade Li-ion batteries can operate for up to 20 years and 5,000 full recharge cycles while offering a wider temperature range (–40°C to 90°C) with the ability to handle 15A pulses and 5A continuous current. (See table below.)

Understand the challenging operating environment

Medical devices often require secure WiFi connections throughout the hospital to form robust and secure networks that are free of potential disruptions.

Hospitals are notoriously complex and difficult RF environments, with large, multi-floor campuses and obstructions such as lead-lined walls making for potential connectivity problems. To complicate matters, hospitals face the risk of interference from a wide range of portable handheld wireless devices possessed by hospital staff, patients and guests. To address these challenges, the Enterprise version of WiFi Protected Access 2, or WPA2, is typically utilized to provide user authentication and data encryption that is HIPAA compliant.

Conclusion

Lacking industry-wide standards, medical device manufacturers, wireless module manufacturers, infrastructure providers and IT personnel must work together to achieve the full potential of the “connected hospital.”

Turning concept into reality is a complex challenge that requires careful due diligence and expert technological deployment to ensure robust performance, comprehensive data security and system reliability. Identifying the ideal battery-powered solution is a critical step that enhances long-term product reliability and reduces the total cost of ownership.

Sol Jacobs is VP and general manager for Tadiran Batteries. He has over 25 years of experience in developing solutions for powering remote devices. His educational background includes a BS in engineering and an MBA.

The opinions expressed in this blog post are the author’s only and do not necessarily reflect those of Medical Design and Outsourcing or its employees.