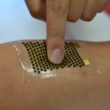

Literal flexibility may bring the power of a new transistor developed at UW–Madison to digital devices that bend and move. [Image from Jung-Hun Seo, University at Buffalo, State University of New York]

The advance could enable manufacturers to create “smart” wireless capabilities for a number of large or small products, including wearable sensors that can curve, bend, stretch and move.

UW-Madison’s transistor is similar to a 20-year-old bipolar complementary metal oxide semiconductor (BiCMOS) transistor, but instead it combines speed, high current and low power dissipation in the form of heat and wasted energy on one surface. The combination of it all creates mixed signal devices that are suitable for portable electronics like cellphones.

“The industry standard is very good,” Zhenqiang (Jack) Ma, the Lynn H. Matthias Professor and Vilas Distinguished Achievement Professor in electrical and computer engineering at UW–Madison, said in a press release. “Now we can do the same things with our transistor — but it can bend.”

BiCMOS flexible electronics are difficult to create because it can take several months with a number of precise and high-temperature steps. Ma and his team avoided that and created their flexible electronics on a single-crystal silicon nanomembrane on a piece of bendable plastic. The process they used eliminated many of the required steps and allowed them to create it in less time and a less expensive cost.

“In industry, they need to finish these in three months,” Ma said. “We finished it in a week.”

The researchers suggest that this method can scale to industry-level production immediately.

“The key is that parameters are important,” Ma said. “One high-temperature step fixes everything — like glue. Now, we have more powerful mixed-signal tools. Basically, the idea is for flexible electronics to expand with this. The platform is getting bigger.”

The research was published in the journal npj Flexible Electronics.