Thanks to a nanotechnology breakthrough by a pair of researchers in the Oregon State University College of Engineering, the lives of diabetics may soon become less complicated.

Glucose monitoring and hormone therapy are daily challenges that never go away for the 3 million people living with type 1 diabetes in America. Also known as juvenile diabetes because it is often diagnosed in youth, type 1 is an autoimmune disorder in which the body attacks its own pancreas with antibodies. Type 1 diabetes accounts for about 5 percent of the diabetic population; roughly 30,000 new cases are diagnosed each year.

Greg Herman, professor of chemical engineering, and Xiaosong Du, postdoctoral fellow, have developed a means of printing transistor-based glucose sensors directly onto a catheter attached to a wearable pump. Diabetics can program the pump to deliver insulin and glucagon, the hormones they need to regulate blood sugar.

The pancreas is the large abdominal gland that regulates blood sugar and makes it possible for the body to derive energy from food. The sensor-equipped catheter combined with the pump acts as an artificial pancreas.

The idea is that the catheter’s integrated electronics will not only keep track of the patient’s bloodsugar levels but also transmit that information to a computerized pump, ensuring that diabetics get the insulin and glucagon they need, when they need it.

“Many of the type 1 diabetes patients in the U.S. are already wearing an insulin pump, so adding glucose sensing to the catheter would greatly simplify their lives,” Herman said.

Herman and Du achieved the innovation through fabricating transparent transistors and biosensors onto the tight curves of a tiny glass tube — a step toward better medical diagnostic techniques: fully transparent electronics combined with sensing and imaging technologies.

Earlier, Herman and Du fabricated amperometric glucose sensors onto a flat polymer film, which was then wrapped around a catheter tube. But when the sensors were tested in an animal model, the devices tended to delaminate — the sensors would come apart from the film, or the film would peel off the catheter.

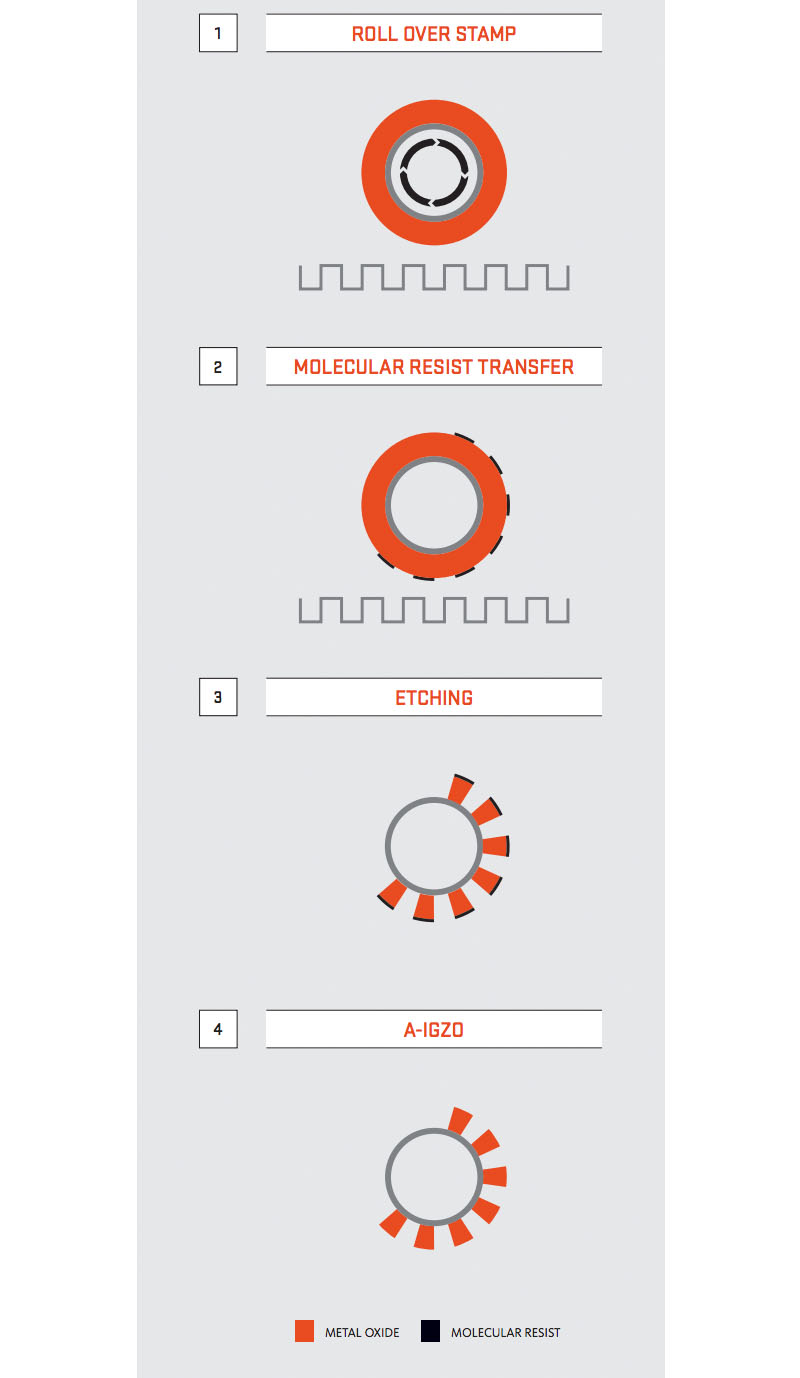

Herman’s collaborators on earlier related research improved the ruggedness of these amperometric sensors. However, in this study, Herman and Du addressed the problem by microcontact printing an amorphous indium gallium zinc oxide, field-effect transistor (a-IGZO-FET) directly onto glass tubes with a 1-millimeter radius.

Traditional patterning technologies like photolithography and e-beam lithography proved troublesome for highly curved surfaces, Herman noted, but microcontact printing worked just as effectively as the researchers hoped.

“The process takes advantage of an elastomeric stamp’s ability to conform to curved substrates with minimal distortion of the printed pattern,” Herman said. “The adhesion of the deposited films to the glass tube is very good.”

How good? Well, plenty good enough to withstand all but the most aggressive intent to remove it.

“For the sensor to come off, you’d essentially have to take a file to it,” Herman said. “It’s much more rugged than what we had before, and the electronic performance is excellent — it’s the same as when fabricated on a flat surface using non-printing methods.”

Catheters are metallic or plastic, so unlike the sensor-equipped, glucose-sensing contact lens that Herman has also worked on, transparency isn’t necessarily required. But they used a glass tube anyway, in part to show off the device’s transparency.

“The idea is that we could start integrating optical fibers that have a-IGZO-FET sensors fabricated directly on them,” Herman said. “Some types of sensing need an optical response for detection, so if we can integrate an optical response with an electronic signal, we can expand the detection to other biomarkers. Fieldeffect sensing may increase the functionality and sensing range of optical sensing systems.”

In this way, transparent field-effect sensing can be melded with electrophysical and neural imaging devices and could greatly improve the sensitivity of an endoscope — a device inserted into the body to provide an internal view.

Technology combines glucose monitoring with an insulin pump to act as an artificial pancreas. Shown here are the steps fabricating the glucose biosensor (a-IGZO-FET) onto a catheter using microcontact printing. The process is repeated three times to form a metal oxide layer.