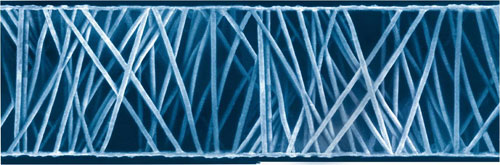

The number of plastic components with integrated membranes is on the rise. These membranes are either used in the automotive industry as pressure-compensating elements, which protect against condensate and compensate for changes in pressure, or they are used as filter media in technical medical components and consumer items.

Until now two steps were needed to process the membranes. Firstly the previously assembled membranes had to be removed from a carrier belt by means of vacuum handling and supplied to the ultrasonic welding tool (sonotrode) to then be welded onto the plastic component via the pneumatic sealing stroke.

MPW – modular ultrasonic punch and weld system by Herrmann Ultrasonics

The HiQ MPW (Modular Punch Weld) machine, a technical development from ultrasonic specialist Herrmann Ultrasonics, can punch and weld at the same time. A cheaper membrane material belt of 5 – 22 mm can therefore be used as the membrane does not have to be tailored in advance.

In one single step, the unit:

- transports the membrane belt by conveyor

- punches the membrane contour

- welds the membrane onto the part

This saves material and reduces the cycle time to less than 2 seconds per weld cycle which translates into a major improvement in OEE (Overall Equipment Efficiency).

The standard optical quality control previously undertaken downstream is not needed because the MPW system has a vacuum monitor to reliably check whether the membrane is correctly punched and positioned. The machine control also features gentle conveyor transport with a splice check, which reduces other sources of error and therefore potential production downtime. A special position measuring system for high cycle rates is wear-free. The Herrmann MPW unit can be flexibly integrated into automation lines or supplied as a manual workstation.

The fully integrated work station will be shown at the PLAST-EX (booth # 2139) in Toronto, Canada.

Herrmann Ultrasonics, Inc.

www.herrmannultrasonics.com