The country has a vibrant health tech environment, fueled in part by its defense industry.

Bill Betten, Betten Systems Solutions

Singer Instrument & Control Singer designed the first PillCam prototype 20 years ago.

In 2016, Israel was rated the fourth most productive innovation center in health technology (a category that includes drugs, devices, and diagnostic technology) on a per capita basis in the world, following Medical Alley (Minnesota), northern California, and Boston.

In 2016, Mazor Robotics had just signed an initial deal with Medtronic. Two years later, Medtronic acquired Mazor and its Mazor X surgical robotic system for $1.6 billion, a record for an Israeli life science company.

So how have things progressed in four years? Today, approximately 1,600 life science companies are active in Israel, employing more than 83,000. As many as 1,394 life sciences companies were established in Israel in the last decade (2009-Q1 2019), and approximately half of them are still active.

To gain additional perspective, I sat down with Gilad Hizkiyahu, who until recently was CEO of a 40-year-old contract design and manufacturing firm, Singer Instruments & Control, to discuss medical technology development in Israel. Excerpts from the interview follow.

BB: Please provide a little background on yourself and your experience in the medical and life sciences development areas.

GH: I am an aerospace engineer with almost 20 years of experience, an MBA graduate and a former major in the Israeli Air Force, where I spent eight years working on aerospace technological projects. Almost 10 years ago, I joined Singer Instruments & Control, which offers turnkey services for design and manufacturing of electromechanical devices, electromagnetic systems and precision mechanic tools. Some of the more interesting projects I worked on include: an implantable nitinol heart apex closure device; a delivery tool for transcatheter aortic valve replacement (TAVR) procedures; a non-invasive, autonomous absolute intra-cranial pressure (aICP) measurement system consisting of a dual-depth ultrasonic transducer; a lightweight, head-mounted 6 degrees-of-freedom (DOF) robotic platform; and an automatic colorectal cancer detection device based on spectral imaging.

BB: How would you characterize Israel’s efforts in the medical and life sciences arena?

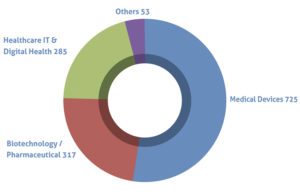

The life science industry in Israel (Image courtesy of the Ministry of Economy and Industry, State of Israel)

GH: Israel is known for its entrepreneurship and innovation, with medical inventions at the top of the list. Some of Israel’s success may be attributed to the Israeli mentality of “chutzpah.” This Hebrew word literally translates to “audacity,” but is more associated with having the amount of courage to dare and dream big, something like the American boxing term “to “punch above your weight.” Mazor Robotics, a small company from the north of Israel, is a good example.

The country’s small size and interconnectedness help support small companies. Everyone knows everyone. The mandatory military service along with defense industries may also explain why so many technologies migrate from defense to medical, as well as talent migration between the fields. An example of this is Given Imaging’s optical PillCam, acquired by Covidien, now Medtronic, for $860 million. Singer designed the first PillCam prototype 20 years ago for an electro-optical engineer from Rafael Advanced Defense Systems, another Israeli company. It combined electro-optical and wireless transmission technologies that enabled the development of a revolutionary pill camera. The miniature PillCam is capable of transmitting video feed from inside the gastrointestinal tract and help physicians diagnose lesions in GI wall areas that have never been examined before.

Other military-to-medical technology switches came with Mediguide’s MPS guidance system, acquired by St. Jude Medical (now Abbott) for $300 million in December 2008 and Biosense Webster’s Carto System, acquired by Johnson & Johnson for $420 million in 1998. Each company’s technology originates from Israeli defense company Elbit Systems’ pilot’s helmet sensors. These electromagnetic sensors, still manufactured by Singer, were the basis for the innovative 3-D navigation solution inside blood vessels. Both solutions were developed and manufactured by Singer to accurately track the tip of a catheter in various procedures, such as cardiac ablation.

BB: What is Singer’s business model?

GH: Singer is used to working with big companies as well as with small startups using various business models. We offer built-to-spec and built-to-print solutions based on either fixed-price, hourly rates or (in some cases) a mix between equity and payment. Our preferred mode of collaboration is built-to-spec full turnkey solutions. We also assist with peripheral activities and provide additional services such as QA support, documentation, lab testing, preclinical trials, etc. Singer also has full-scale production capabilities under ISO 13485 regulation.

BB: Please describe your collaboration process, particularly with companies outside of Israel?

GH: We collaborate closely customers’ engineers, clinicians and project managers, giving them unlimited access to our facility, and in some cases, even as a user in our server, as well as access to our directory of documents related to their project. Our formal documentation is in English and our standards of work are international, so we face no issues when working with international customers. When we work with companies outside Israel, we place more effort on effective communications via phone calls and video calls, as well as continuous email communication as the project progresses with direct access to the project manager.

BB: How has COVID-19 affected the development of medical device and life science projects in Israel?

GH: The COVID-19 pandemic spurred many related startups in Israel and encouraged Israeli companies in other fields (defense, IT, industrial and others) to divert some of their resources and efforts toward developing COVID-19 solutions. None of Singer’s projects were negatively affected by the situation as we are considered an “essential company.” The Israeli Innovation Authority also stepped in and offered grants for companies developing new solutions to address the COVID-19 crisis, so we found ourselves also assisting startup companies with grant proposals and validating their technological concepts.

Bill Betten is the president of Betten Systems Solutions, a product development realization consulting organization. He most recently served as director of business solutions for Devicix/Nortech Systems, a contract design and manufacturing firm. He was also VP of business solutions at Logic PD, medical technology director at TechInsights, VP of engineering at Nonin Medical, and has worked in a variety of technology and product development roles at various high-tech firms.

The opinions expressed in this blog post are the author’s only and do not necessarily reflect those of Medical Design and Outsourcing or its employees.