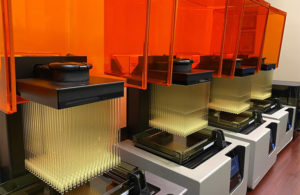

(Image courtesy of University of South Florida Health)

Investigators in a multisite clinical trial have found that 3D-printed alternative nasal swabs work as well, and safely, as the standard synthetic flocked nasal swabs in testing for COVID-19.

Results of the study by the University of South Florida Health (USF Health) Morsani College of Medicine and its primary hospital affiliate, Tampa General Hospital (TGH), were published online Sept. 10 in Clinical Infectious Diseases.

A team that included USF Health researchers in the Departments of Radiology and Infectious Diseases and colleagues at TGH worked with Northwell Health and 3D-printer manufacturer Formlabs to design, test and produce a 3D-printed nasal swab prototype as a replacement for commercially-made flocked nasal swabs. Conventional swabs feature a bushy tip coated with nylon flock; the USF Health doctors designed a tip with a 3D-printed, textured pattern able to capture a sufficient sample for COVID testing while keeping patient safety and comfort in mind.

The team completed bench testing (24-hour, 3-day, and leeching) using respiratory syncytial virus as a proxy for SARS-CoV-2, as well as local clinical validation of the final prototype fabricated with FDA-approved nontoxic, surgical-grade materials, in mid-March 2020.

The larger-scale clinical trial began in late March with 291 symptomatic adults undergoing COVID-19 screening at TGH, Northwell Health and Thomas Jefferson University Hospital. The 3D-printed nasal swab was compared to the standard synthetic nasal swab across three SARS-CoV-2 testing platforms FDA-authorized for emergency use — a modified version of the Centers for Disease Control and Prevention’s real-time reverse transcriptase PCR diagnostic panel, and two commercial molecular diagnostic tests.

“This trial provided the first rigorous head-to-head comparison to make sure that the 3D swab performed as well as the standard,” said principal investigator Dr. Kami Kim, professor and division director for infectious disease at the USF Health Morsani College of Medicine, in a news release. “Across all three platforms used in our study, we demonstrated that the commercial swab and the 3D-printed swab were comparable for accurate detection of COVID-19 infection.”

For both types of swabs, the only adverse patient reaction documented during the trial was a few instances of slight nasal bleeding. The cost of materials per 3D-printed nasal swab ranges from 26¢ to 46¢ while commercial swabs cost about $1 each, the authors reported.

Given the ongoing need for widespread COVID-19 testing, the study authors concluded that 3D printing technology offers a viable, cost-efficient option to address swab supply shortages, particularly when local hospitals or other clinical sites already have 3D printing labs equipped to print and process the devices.

USF Health shared the information with hospitals, clinics, governments and international agencies experiencing supply chain shortages. Since the first batches of 3D-printed swabs were processed, tens of millions of the devices have been used in 22 countries, the authors noted.