Three production techniques can reduce the colonization of bacteria on devices made of silicone for placement inside the body. Tests have shown that the newest method shows promise.

Andrew Gaillard, Trelleborg Sealing Solutions

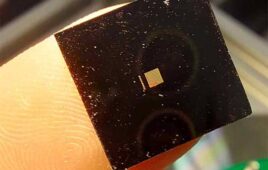

Applying active pharmaceutical ingredients to silicone has a powerful inhibitory effect on the growth of Staphylococcus aureus, according to the tests Trelleborg conducted. [Image courtesy of Trelleborg]

Though silicone is biocompatible and biostable, it is not immune to bacterial colonization. Three techniques can reduce this colonization:

- Coating with active pharmaceutical ingredients (API);

- The addition of API to raw silicone;

- The impregnation of vulcanized silicone with API through immersion

API coatings are applied to silicone catheters by spraying or dipping. Though probably the most cost-effective method of treatment, achieving good uniformity and long life is challenging. The coatings may crack or peel, and in some cases, it can be hard to apply a coating to the inner lumen surface of a catheter.

The second and well-proven method used to prevent bacterial buildup involves adding antibiotic API, such as chlorhexidine, gentamycin, rifamixin, or doxycycline in powder form to silicone raw materials using various types of mixing equipment. After homogenization, the silicone-drug mixtures can be formed into desired shapes and vulcanized using various fabrication processes, including molding and extrusion.

The key advantage of this method is that the API is effectively and consistently present within the silicone. However, compatibility of the API with the silicone grade must be confirmed as some API can inhibit or even poison the cure system of certain silicones. Also, certain drugs are not stable at elevated temperatures. In these applications, silicones that can be vulcanized at relatively low temperatures may be used, but this limits the type of API that can be used.

The third and newest method to reduce bacterial colonization is the impregnation method. Most silicone medical components are manufactured from raw material formulations containing polydimethylsiloxane (PDMS) polymers reinforced with amorphous noncrystalline silica. Vulcanized PDMS elastomers can be readily swollen by immersion in various organic solvents. Because of this characteristic, vulcanized silicone can be immersed in a solution containing API to impregnate the vulcanized silicone with active drugs.

The advantage of the impregnation method of vulcanized silicone with API is that the API cannot interfere with the cure chemistry of the silicone and that the API is uniformly impregnated on the surface of the inner lumen.

Immersion is usually conducted at room temperature, thereby eliminating concerns regarding the thermal degradation of the API, and thus expanding the types of APIs that can be used. In addition, dissolved drugs are impregnated within the silicone elastomer as discrete molecules. This minimizes concerns and costs associated with specifying and maintaining a particular size and distribution of particles.

Immersion experiments have conclusively demonstrated the mass transfer of two antibiotics, clindamycin hydrochloride (CLIN) and rifampicin (RIF), from chloroform solutions to silicone tubing. Following these tests, a study of the Kirby-Bauer zone of inhibition (ZOI) assessed the impact of drug content of silicone tubes on the gram-positive coccal bacterium, Staphylococcus aureus.

This in-house study showed that drug-impregnated tubing had a powerful inhibitory effect on the growth of Staphylococcus aureus and revealed clear zones of inhibition surrounding test articles. As expected, the higher the drug concentration, the larger the ZOI. Though still in the early stages of use, the impregnation method looks positive, potentially allowing the expansion of the drug types that can be delivered via silicone-implantable devices.

Andrew Gaillard is global director, Healthcare and Medical, at Trelleborg Sealing Solutions.

The opinions expressed in this blog post are the author’s only and do not necessarily reflect those of Medical Design and Outsourcing or its employees.