Matthias Dorsch | Product Manager | VARTA Microbattery

Designers of portable medical devices and electronic products are familiar with the challenges of space and weight reduction. There seems to be no limit to consumers’ requirement for making devices thinner, lighter, and sleeker. Consider an in-ear speaker or earbud as a stand-in for a medical device, with a form factor constrained by the size of the human ear.

In electronics, the constant reduction in a circuit’s size predicted by Moore’s Law has helped designers do more using less space. But in the domain of energy storage, chemistry, not electronics, determines the pace of size reduction, and unfortunately chemistry has no equivalent to Moore’s Law to drive reductions in battery cell sizes.

Still, innovation in battery technology still provides answers to OEMs’ demand for more energy in less volume. This article describes how improvements to a new type of coin cell are helping some of the industry’s smallest electronics run longer between charges than previously possible.

The drawbacks of lithium technology

In medical and consumer electronics, various types of lithium-ion technology have been widely adopted: Lithium-ion chemistries for rechargeable batteries provide better ratios of energy-capacity-to-volume and energy-capacity-to-weight than any other battery chemistry in mass production. That’s why most portable products with small size and weight requirements most often contain lithium-ion rechargeable cells.

In the past, OEMs faced extreme difficulties in scaling down lithium-ion batteries for use in devices much smaller than a mobile phone. The wireless headset using Bluetooth technology illustrates the problem.

In previous years, wireless headsets would use a custom lithium-ion battery assembly in which the cell was enclosed in an aluminium foil pouch. Flying leads made the connection to a host device.

This complex assembly was relatively bulky. Worse, pouch-style batteries are difficult to handle on a production line. They require manual assembly, making them inherently prone to inconsistent quality and damage. In addition, the pouch enclosure is prone to premature failure when subjected to shock and vibration. This is undesirable in earphones, which might be frequently dropped during fitness activities.

Lastly, a custom part that is unique to one customer carries a higher supply-chain risk for the customer than a standard part, which is produced and stocked in high volume for multiple customers.

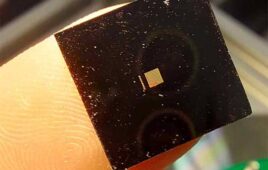

These drawbacks led to the development of an alternative for tiny devices, such as wireless headsets: The VARTA CoinPower, the industry’s first rechargeable lithium-ion battery in a coin-cell form factor to offer the energy capacity required by small wireless consumer devices. The first generation of these coin cells was available in 12mm and 16mm diameters and provided an average 3.7V output.

Behind the introduction of the CoinPower cells lay technologies patented by the company, which allow for the automated production of coin cells with coiled electrodes. This method for coiling electrodes makes better use of the cylindrical space inside the case. In addition, VARTA Microbattery developed a patented design for closing the case. These technologies provide a higher energy density than previous li-ion coin cells with conventional stacked or layered electrodes. Automated production at the company’s factory in Germany is highly repeatable and ensures that each manufactured unit operates according to its specification.

The higher capacity of the CoinPower product provids a crucial advantage for small electronic devices, and a strong, rigid stainless steel case offers easy assembly into end equipment, with almost no risk of damage, and a high level of precision in the mechanical design of the battery assembly. The case also has a high tolerance for shock and vibration.

It’s important to note that the supporting electronic circuit is also small. A CoinPower cell requires only a standard circuit protection device, available at low cost from suppliers such as Seiko and Mitsumi, plus two passive components. A wide range of ICs for standard battery chargers can control the cell’s charging process. The footprint of this circuitry is considerably smaller than the complex PCB generally implemented in custom battery packs. What’s more, the supporting circuitry need not be close to the battery, giving system designers freedom to optimize their board layout and mechanical design.

Device manufacturers can avoid the design, production cost, and risk associated with custom battery packs because the battery is a standard part, and the supporting circuitry is easily implemented using standard components.

There’s another important reason for the wide use of the first-generation product: Safety. Most lithium-ion batteries work safely within their rated voltage and current limits. But over-current or over-temperature conditions can cause thermal runaway, leading the device to explode or catch fire. For this reason, a lithium-ion battery requires safety and protection circuitry to electrically disconnect the cell when it exceeds safety thresholds.

The advantage of the VARTA CoinPower cell is that it offers an integrated protection mechanism, independent of external circuitry, which shuts the cell down before it enters an unsafe, over-current condition. This provides an extra level of protection for the user’s safety.

The Bragi miniature earphone, in the lady’s ear, is also a complete music storage device powered by a rechargable VARTA Microbattery. The unit provides inspiration for small medical devices.

This Current Interruption Device is a mechanical fuse: When the pressure inside the cell rises above a certain level – as happens when the cell is charged at an excessive current or voltage – the upper and lower casings come apart by a small, controlled amount sufficient to break the circuit and permanently disconnect the battery. CoinPower cells are actually rated to withstand extreme 12V/3C over-charging conditions, which put a far greater stress on the cell than industry standards specify. (1C is the current draw that will discharge a fully charged battery in one hour.)

Improvements to the li-ion coin cell

The li-ion coin cell has become the preferred battery choice for manufacturers of extremely space-constrained, portable devices requiring a high energy capacity of 50 mAh or more. It’s found uses in consumer devices and medical and industrial equipment in which durability, high capacity and long cycle life are important.

The advantages of the original CoinPower product now have been extended with the introduction of the ‘A2’ and ‘A3’ series of cells. Improvements to chemistry and production techniques cells have increased their capacity, as well as extended their cycle life. The dimensions and energy capacity of these cells provide the best fit for the size and shape of the human ear, and for the requirements of manufacturers of earphones and ‘true wireless’ technology.

The Dash wireless earphones are powered by VARTA’s Microbattery and come from manufacturer BRAGI. The units are a lot smaller than these appear.

Standard cycle life ratings for rechargeable batteries measure the fully charged capacity of the cell, as a percentage of its capacity when new, after 500 charge/discharge cycles at an operating temperature of 20°C (68°F). The formal specifications supplied by VARTA Microbattery show that, when stressed by executing 500 fast charge/fast discharge (1C/1C) cycles in the laboratory, the CoinPower A2 cells still retain more than 80% of their original capacity. Under gentler operating conditions (0.2C/0.2C), this value for remaining capacity rises to more than 85% after 500 cycles. In real-world applications, users are able to achieve outstanding cycle-life performance: customers typically report cells lasting for more than 1,000 cycles when mounted in an end product.