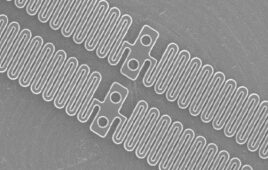

Toray Industries offocials think the bio-absorbable polymer could be used as a scaffolding material in regenerative medicine. [Image courtesy of Toray Industries]

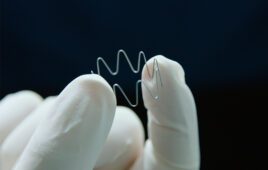

Proprietary functional polymer design technology allows the polymer to recover its original shape even after being stretched 10 times the original length, the company explained in a March 14 announcement. Toray also has identified a way to improve the polymer’s degradation speed by 10 times through hydrolysis.

Here’s how Toray officials describe the substance:

“Originally, polylactic acid and polyglycolic acid, which are bio-absorbable polymers, tended to form crystals (crystallinity) and become hard, which made it difficult to provide both flexibility and rupture resistance properties. Toray developed a special copolymerization method using lactide, dimers of lactic acid, and caprolactone, and realized both flexibility and rupture resistance enabling recovery without rupture even after being stretched 10 times the original length. Further, by highly controlling the hydrolysis of this polymer, it created a bioabsorbable polymer with the decomposition speed improved 10 times.”

Toray officials expect to apply the new polymer materials technology to applications including tissue reconstruction treatment such as regenerative medicine — where there is a need for flexibility and rupture resistance to accommodate organ and tissue movement.