Until portable devices are powered by the wearer’s movement, they will require batteries. The number of portable battery-powered medical devices has grown exponentially over the past five years and that trend will continue. The ever-shrinking power source is driving a few other big trends in medical device design, including shrinking devices, a greater variety of wearable monitors, and smaller batteries with correspondingly smaller holders and connections. Outside influences driving trends are environmental concerns such as selecting materials that are ROHS-compliant and more environmentally friendly.

“We design a lot of battery holders for medical devices,” says Keystone Electronics’ application engineer Joe Rosenblum. “The holders include a standard line that covers a wide array of battery shapes, such as cylindrical, coin cells, and 9V, and for different chemistries. Although the chemistries are changing slowly, battery sizes are getting smaller, especially for personal-use devices, so their holders must be smaller.”

No surprise then that lithium ion cells are used more often. They are rechargeable, improve on energy density, and provide a higher output than previous cells. In addition, battery shelf life has rapidly improved with the introduction of many battery variations with a range of lower discharge rates, as in the case of lithium-ion varieties.

Although component-connection companies have a place in the supply chain, they usually don’t influence the design of the medical device. “However, we have an engineering team that designs custom connectors. A development engineer’s initial comment while showing a new device’s specs is often, ‘This is what we want,’” says Rosenblum.

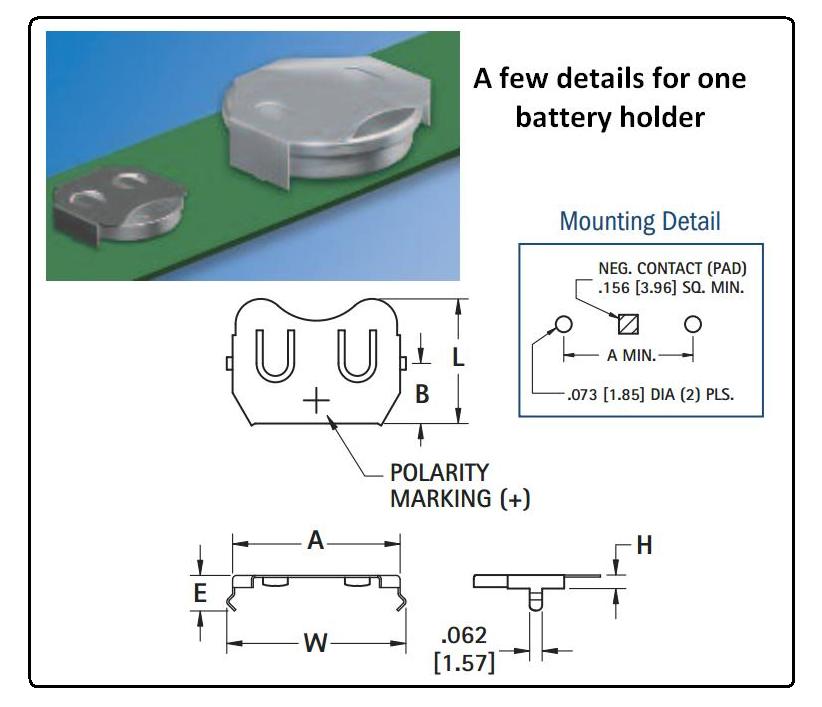

The connecting components that securely retain batteries regardless of shape or position, while easing cell installation and replacement, call for clever manufacturing techniques. Custom capabilities have accommodated the rapid growth of non-standard designs along with battery holders to include retainers, contacts, clips, snap-ons and snap-ins for coin-cell and button-cell batteries, as well as strap assemblies for dual and multiple holders.

Balancing battery strength and size is another concern. One solution is to combine the use of plastic and metal sub-components, which also answers space and cost considerations. Retainer clips lock-in batteries securely and withstand shock and vibration.

In addition, where low electrical resistance is critical, contacts made of alloys such as phosphor bronze and beryllium copper serve as battery contacts as well as interconnects.

Lastly, improving reliability and durability of connectors or contacts are of major importance. That puts an emphasis on plating, because its selection depends on factors such as galvanic reaction, conductivity, hardness, solderability, corrosion, and environmental effects. Galvanic reactions occur when dissimilar materials contact each other and corrode. Plating dissimilar metals with compatible plating helps protect base metals. The development and use of proper connective plating is directly correlated with longer-term battery life. Instead of three or five years, certain cells can now be expected to last 10 years.