Josh Blackmore, Global Healthcare Manager/Ben Gerjets, Product Development Engineer/RTP Company

In an emergency situation, there is only one “shot” to use a single-use injection pen, safety syringe or other medical device. One of the key design challenges for single-use medical devices is ensuring the “stiction” free movement of the device on the first and only usage.

In an emergency situation, there is only one “shot” to use a single-use injection pen, safety syringe or other medical device. One of the key design challenges for single-use medical devices is ensuring the “stiction” free movement of the device on the first and only usage.

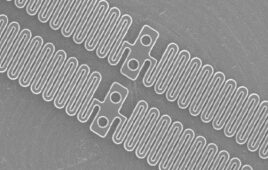

Single-use medical devices with moving parts have a unique set of performance criteria that include low forces, a short movement path and low speeds. Many of these devices use a secondary external lubricant, such as silicone, for quiet and smooth operation. These secondary operations can add significant cost, have difficult clean-up procedures and require additional quality inspections to ensure lubricant is applied correctly.

A more cost-effective and manufacturing-friendly alternative is introducing internal lubrication by compounding the lubricant within the plastic. This improves dispersion of the lubricant and eliminates the added cost of secondary operations. Although standardized thermoplastic tribology tests use conditions that are predictive for long-term wear performance, they don’t help in the selection of materials to eliminate the stick-slip phenomenon that’s critical to the performance of single-use medical devices.

Accurately predicting results

To assist in the material selection process, a custom oscillation routine was created for a thrust washer machine, and was used to mimic the movements, pressures and velocities found in the moving parts of typical auto-injection pens and syringes. Using this test method, engineers explored base resins including polycarbonate (PC), acetal (POM), acrylonitrile butadiene styrene (ABS), polycarbonate/ABS Alloy (PC/ABS), high-density polyethylene (HDPE) and polybutylene terephthalate (PBT). These resins were tested in a variety of combinations with friction-reducing additives including polytetrafluoroethylene (PTFE), perfluoropolyether (PFPE) oil and a selection of silicones, along with RTP Company’s All Polymeric Wear Alloy, known as APWA Plus. The combination of two compounds, one on each side of the assembly and tested against one another, is referred to as a “friction pairing.”

The data tell a story

For each friction pairing, engineers measured the Static and Dynamic Coefficients of Friction (COF), looking for the lowest and most consistent static COF values possible with a minimal difference between static and dynamic COF. The threshold representing the smallest delta between the two measurements has been coined by RTP Company tribologists as the “Glide Factor.”

Consistent, repeatable tests showed that the ideal friction pairings exhibited low Static Coefficient of friction (< 0.15) and a Glide Factor of < 0.015. A low Glide Factor is an indication that the mating surfaces will perform better, with less sticking, slipping, and inconsistent sliding.

By conducting numerous statistically valid tests and gathering performance data, engineers came to a number of conclusions regarding materials selection for single-use medical devices, including resin selection, internal lubricant selection and the challenges of factors such as pressure and load.

Benefits of using tribology data

The data collected let designers make informed choices, rather than spend valuable resources on a conventional trial-and-error approach to medical device design and manufacturing. Accurate, up-front data also reduces the cost per part and time to market.

In addition, the data shows that costly external lubrication and processing steps can be reduced or eliminated by using an internally lubricated compound. Most importantly, concrete material data helps ensure optimal medical device performance and safety.