The nickel-and titanium-alloy known as nitinol is a super-elastic shape-memory alloy responsible for major advances in medical technology over the last 15 years. When pursuing a manufacturer to produce a new Nitinol-based implant or device, it’s important to consider a number of factors.

Norman Noble, Inc.

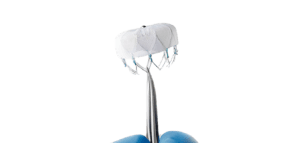

Nitinol is a highly elastic material that’s processed to maintain a required geometry. Its properties, combined with high fatigue resistance and an ability to provide constant force over a wide range of displacements, makes it ideal for use in numerous medical implants and devices, including vascular stents (cardio, AAA, peripheral, carotid, venous, neuro), transcatheter heart valves, vascular closure implants, neurovas-cular clot pullers, flow diverters, vena cava filters, orthopedic anchors, and atrial fibrillation devices.

As well-suited as nitinol is for vascular implant applications, few manufacturers are able to produce finished goods with it. The major barriers to working with nitinol are:

• Knowledge. Working with the alloy requires extensive knowledge of its mechanical properties and fatigue characteristics.

• Low machinability. As a raw material, nitinol is difficult to machine with conventional technol-ogies. Multiple proprietary manufacturing processes are required to produce even the most basic nitinol-based device.

• Electropolishing and passivation: To protect against the harmful release of nickel into the human body, electropolishing or passivation are required to create a protective titanium oxide layer.

• Process validation: Nitinol implant manufacturing requires strict process controls and validation to meet the finished material specifications.

Consider these factors when pursuing a manufacturer to produce a new nitinol-based implant or device.

Raw material sourcing

Before committing to any manufacturer, it’s crucial to know how they’ll source nitinol for a given project. An original equipment manufacturer’s (OEM’s) ability to supply the market with product depends directly on the contract manufacturer’s ability to source the raw material required to maintain continuity of supply.

A sustained disruption in supply is often catastrophic for OEMs. At a minimum, ensure that the contract manufacturer will qualify and validate two sources of nitinol for production. A disruption in the material quality from the primary source can be quickly resolved by increasing supply from the second.

Equally important, the quality, type (sheet or tube) and characteristics of the nitinol supplied by any given raw material producer is variable. The manufacturer who regularly sources material from many suppliers is able to best match the raw material to your design requirements and product application.

Design for manufacturability and finite element analysis (FEA)

It’s also important to evaluate product design specifications during the prototyping stage to identify opportunities to reduce cost without compromising the manufactured part’s intended function. Any cost-reducing design changes must be implemented prior to design freeze.

For any prospective new device design, extensive design and testing services should be available to help the design engineer perform FEA. This ability to model and simulate mechanical behavior reduces the time needed between design iterations, a critical step in the race to bring products to market.

Dedicated process engineering

Each manufacturing step requires the contract manufacturer to custom-design that operation for any particular product design. This is done by designing, testing and refining the step using the same model and type of equipment and conditions that will be used in production. The capability to design and manufacture all shape-set tooling and fixturing for each process step in-house is essential to ensure the highest level of quality and process control.

Testing should be completed by experienced engineering personnel and using designated equipment and facilities dedicated solely to process development.

Manufacturing parts complete

Producing finished nitinol parts is a complex, multi-phase endeavor requiring years of experience and numerous manufacturing and finishing capabilities. It’s important to understand up front if your supplier can completely manufacture your part in-house using special nitinol processing techniques. Can they handle all manufacturing and finishing required to produce a marketable product without outsourcing any steps?

By handling all steps in the manufacturing process, the supplier can tune each step based on its knowledge of the upstream or downstream capabilities. This produces the highest level of quality assurance and process control.

Finishing by electropolishing

A product’s fatigue and corrosion resistance are major factors in its performance. Finishing polishes, passivates, removes micro-cracks, and deburrs the workpiece. There are various finishing methods. Electropolishing produces the best results for corrosion resistance and biocompatibility. The electropolishing process can be designed to sharpen or round dimensional features to meet product requirements. Verify that the supplier will use electropolishing and passivation on the finishing of implants.

100% dimensional inspection

One of the last steps in producing a device, dimensional inspection, is also one of the most critical to verifying a consistent, high-quality component that meets design specifications. A manufacturer must know if a supplier has the capability to provide validated, 100% dimensional inspection on each implant. Anything less invites risk to the patient and the OEM.

Validation and inspection

All operational process steps and tooling used to manufacture Nitinol implants must be within established and tested control limits. Validation ensures that the manufacturing process conforms to the control limits. Inspection ensures the manufacturing output does as well. Insist on 100% automated inspection for peak quality.

Validation must be conducted in accordance to ISO 13485:2012 standards. The contract manufacturer should employ an experienced validation engineering team to provide the strategy and protocols needed to complete all validation activities.

Additionally, the contract manufacturer should have in-house verification technologies to support validation, including:

• Metallography expertise and Scanning Electron Microscopy, which is required to verify removal of Heat Affected Zones.

• Corrosion testing capabilities per ASTM F2129.

• Bend and Free Recovery and Differential Scanning Colorimeter, to verify material Austenite Finish, Mf, Ms, and As transformation temperatures.

Athermal laser machining for next-generation implants

The demand for smaller devices and entirely new neurovascular applications requires even more innovative manufacturing methods. If the ability to test and produce next-generation implants is a priority, determine if a contract manufacturer has an athermal laser machining capability.