[Image courtesy of Sensata Technologies]

James McNamara, Sensata Technologies

Originally developed for audio speakers, voice coil actuation technology is now being utilized to provide precise and reliable motion control for a wide range of medical applications.

Although it has been around for decades, VCA technology is still a mystery to many design engineers as, until recently, the application spaces for which it was a cost-effective solution were relatively restricted. Many designers had to settle for more traditional, but less flexible, solenoid-based devices. Now that powerful microcontrollers (MCUs) and precise and efficient drivers are readily available, advanced linear motion designs using VCAs are easier and less expensive to implement.

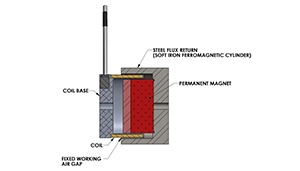

Used in a wide range of medical and industrial applications, an axial voice coil actuator is composed of a permanent magnet situated within a moving tubular coil of wire, all inside of a ferromagnetic cylinder. When current runs through the coil, it becomes magnetized and repels against the magnets, producing an in and out, back and forth motion. [Image courtesy of Sensata Technologies]

VCAs offer many benefits to the medical design engineer. They are very simple and extremely robust, yet are as exactly precise as the input given them. VCAs accelerate smoothly and quickly to any position within their stroke with nearly zero hysteresis and are only limited by the system’s position-sensing precision and driver capability. Because of this accuracy, these devices lend themselves extremely well to applications such as medical devices, robotics and industrial process equipment.

Precision control for medical devices

One application area that demands critical precision is the medical industry. Devices like drug-dispensing pumps and ventilators do not work on approximations — every microliter of liquid (or air) has to be carefully measured and managed. The precise motion control a VCA-based solution provides in a medical flow-management system increases accuracy without complexity or bulk.

The challenges in designing medical devices are compounded beyond strict performance and regulatory standards; there is also the need for small and lightweight devices to allow for portable use by caregivers moving room-to-room in a facility. This demand for performance in a constrained space lends itself well to a VCA solution.

VCAs such as Sensata’s LAH08-15-000A are often used to control inhalation and exhalation valves on ventilators as their precision, reliability, and small size meet the demands for life-critical applications in the medical industry. [Image courtesy of Sensata Technologies]

Small VCAs measure just 0.75 in. in diameter and weigh only 2.3 ounces, yet can deliver a peak force of nearly 2 lbs. in an operating stroke of ±2 mm with low hysteresis, zero cogging, high acceleration and a long-life cycle. This accurate linear motion control can also serve other precision medical systems like anesthesia machines as well as ultrasound probes, blood analyzers, and lab equipment.

Development tools to help the medical design engineer

Sensata’s Self-Contained Voice Coil Actuator developer kits enable designers to quickly evaluate and implement a VCA-based motion solution. [Image courtesy of Sensata Technologies]

James McNamara is a senior applications engineer at Sensata Technologies, where he is an expert on voice coil actuator technology. He has been with the company for 12 years and has 40 years of experience working in the electric motor industry. McNamara holds a BS degree from National University in Computer Science.

The opinions expressed in this blog post are the author’s only and do not necessarily reflect those of Medical Design and Outsourcing or its employees.