Linear motors produce linear motion, not rotary motion, as do most motors. Like many rotary motors, linear motors consist of a coil (primary part or forcer) and magnets (secondary part). Although there are many types of linear motors, brushless ironcore and ironless designs prevail in automation and positioning applications. Each has special construction features and performance characteristics.

Linear motors produce linear motion, not rotary motion, as do most motors. Like many rotary motors, linear motors consist of a coil (primary part or forcer) and magnets (secondary part). Although there are many types of linear motors, brushless ironcore and ironless designs prevail in automation and positioning applications. Each has special construction features and performance characteristics.

Linear motors offer several advantages over belts, screws, and other drive mechanisms, including almost unlimited lengths, low maintenance, and higher accuracy and repeatability. There are no mechanical-transmission components – such as pulleys, couplings, or gearboxes – to introduce elasticity and backlash. The system’s accuracy and repeatability are determined by the controls and do not degrade over time. The lack of rotating or sliding components also means these motors are almost maintenance-free, with only the support bearings (linear guides) requiring periodic maintenance.

Linear motors can also provide unlimited travel by simply stacking magnet tracks end-to-end. (It’s important to note, however, that cable management may become the limiting factor for systems with unusually long stroke lengths.) And with the ability to use more than one primary part on a single secondary part, systems can be built with multiple carriages performing independent movements, simplifying the system design and reducing space.

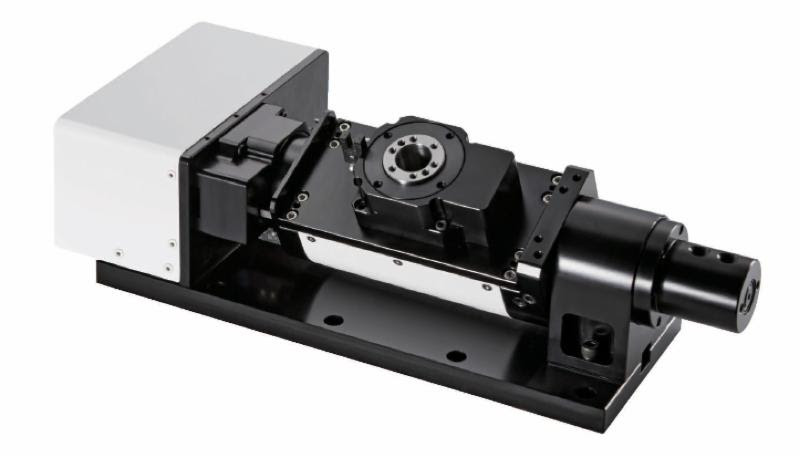

Ironcore linear motors, as their name suggests, are constructed with the coils of the primary wrapped around an iron core. The secondary part is typically a stationary, flat magnet track. Ironcore linear motors are characterized by their high continuous force and ability to move large loads, which make them ideal for machine tool, injection molding, and pressing applications.

One downside of ironcore linear motors is an effect known as cogging, which is caused by the magnetic pull of the secondary on the primary as it moves across the magnet track. This pull creates a detent force that degrades the motor’s smoothness of motion. Manufacturers have various ways of reducing the cogging effect.

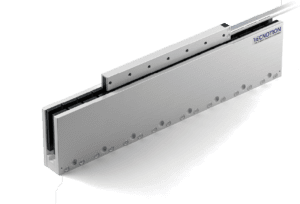

Ironless linear motors eliminate iron from the primary by using coils embedded in an epoxy plate. This reduces mass and lets them achieve highly dynamic motion. Where iron core linear motors consist of a flat magnet track, ironless linear motors typically consist of a U-shaped magnet track, with two plates of magnets facing each other. This reduces heat dissipation and means that ironless motors have lower thrust forces than iron core motors. But their lower mass (due to a lighter primary part) gives them better acceleration and short settling times, making them ideal for precise, rapid movements.

Another plus for ironless versions: No attractive forces between the primary and secondary parts, because there is no iron in the primary. This makes them easier and safer to assemble. It also means that the supporting bearings need not be sized to accommodate the attractive forces, and will generally have a longer service life.

Learn more about linear motors from Medical Design & Outsourcing sister site Linear Motion Tips.

This post was originally published in 2015 and updated in 2024.