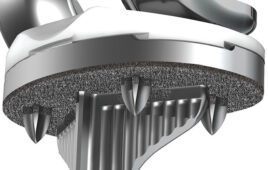

[Image from Bodycote]

Because of its diffusion characteristics, kolsterising is ideal for medical devices that require corrosion, wear and fatigue resistance. It can eliminate delamination and metal debris, as well as galling in stainless steel alloys to improve wear resistance and fatigue strength. There is an FDA master file available for use in medical devices and it is biocompatible.

This process allows for the use of more common materials, such as 316L, to achieve the performance of materials like 465 and Nitronic. Kolsterising also offers consistent diffusion depth, increased abrasive wear and cavitation erosion resistance, elimination of galling and fretting and scratch resistance. It also does not affect magnetic properties of metal alloys.

The enhancements are accomplished by adding large concentrations of carbon atoms which form high compressive stresses at the surface. The compressive stresses along with occupation of the interstitial sites by the carbon atoms cause a significant increase in the surface hardness of the material, which improve mechanical and tribological properties. Also, because no phase change takes place, the final part’s dimensions, surface finish, and corrosion resistance are maintained.

For more information, visit Bodycote’s website at bodycote.com/s3p or contact Derek Dandy, medical market development engineer, at derek.dandy@bodycote.com.